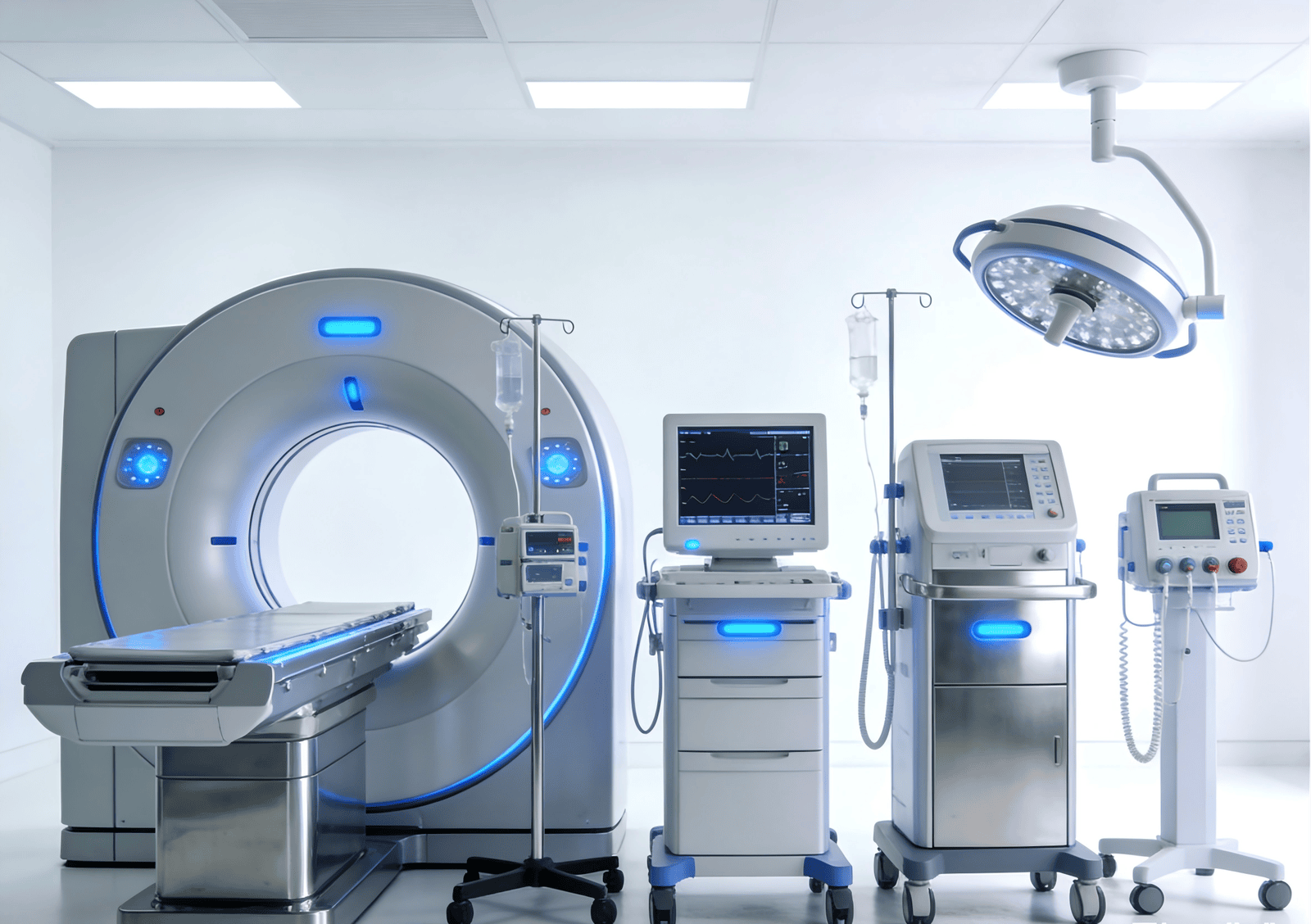

In the fast-growing global medical technology market, lithium batteries are now the main power source. They power many healthcare devices. These devices include portable patient monitors, ventilators, defibrillators, infusion pumps, surgical tools, and home rehabilitation equipment.

As medical devices become more mobile, they need better batteries. A growing demand for safe and high-performance lithium battery solutions exists. These batteries should have higher energy density, greater reliability, and longer operating times.

하지만, selecting the right medical lithium battery manufacturer is not as simple as choosing a supplier for consumer electronics. Medical devices involve life-critical applications, strict regulatory requirements, and rigorous reliability standards. A battery failure could mean equipment downtime, medical delays, or even patient harm.

Choosing a reliable medical lithium battery manufacturer is crucial for a medical device company.

This article offers a detailed 2000-word guide. It explains how to evaluate, compare, and choose the best lithium battery manufacturer for medical uses. This shows why 동관 이잔 전자 기술 유한 공사(동관 이잔 전자 기술 유한 공사) is a trusted partner in the global medical power industry.

1. Why Medical Devices Require Specialized Lithium Battery Manufacturers

Lithium batteries used in medical equipment are significantly different from batteries for consumer electronics or electric mobility. Key differences include:

1.1 Higher Safety Requirements

Medical devices often operate in hospitals, ambulances, clinics, or home-care settings. Any thermal runaway, swelling, leakage, or malfunction could cause critical risk.

Therefore, medical batteries must meet:

- Strict thermal management design

- Zero-defect reliability

- Anti-explosion and anti-short-circuit structure

- Stable chemical performance

- High-precision BMS protection

1.2 Life-Critical Reliability

Devices such as ventilators, oxygen concentrators, and defibrillators must work flawlessly even under extreme conditions. Power interruption is unacceptable.

This requires:

- Extremely low failure rates

- 긴 주기 수명

- High temperature resistance

- Real-time monitoring BMS

1.3 Global Certifications

Medical equipment is sold globally. Batteries must comply with:

- IEC62133

- UL2054 / UL1642 / UL62368

- UN38.3

- CE / PSE / KC

- FDA / MDR related documentation support

- RoHS, REACH, MSDS

Manufacturers without proven certification experience cannot reliably support medical clients.

1.4 Custom Engineering Capabilities

Medical equipment sizes vary widely. Off-the-shelf battery packs rarely meet the exact requirements.

Quality manufacturers must offer:

- Custom cell configuration

- Custom casing

- 맞춤형 BMS

- Custom communication protocols (UART, SMbus, CAN, I2C)

- Custom safety protection

2. Key Criteria for Choosing a Medical Lithium Battery Manufacturer

Below are the essential factors companies should evaluate.

2.1 Professional Experience in Medical Applications

A qualified medical battery manufacturer should have extensive experience with different medical scenarios, such as:

- Patient monitoring systems

- Portable ultrasound devices

- Infusion pumps

- Ventilators

- AED defibrillators

- Rehabilitation and physiotherapy devices

- Wearable medical equipment

Experience is critical because medical applications involve:

- Lower tolerance for failure

- More complex design challenges

- Specialized testing procedures

동관 이잔 전자 has helped global medical brands for over 10 years. They provide Lithium-ion and LiFePO4 battery solutions. Their products offer safe power for hospitals and home care.

2.2 Compliance With International Certifications

Certification is one of the strongest indicators of reliability.

Essential Certifications Include:

- UN38.3 (mandatory for shipping)

- IEC62133 (international standard for portable lithium batteries)

- UL2054 / UL1642 (safety testing for US markets)

- CB / CE / KC / PSE

A manufacturer that cannot produce certified test reports and historical project cases should not be considered for medical projects.

동관 이잔 전자 provides complete testing documentation and certification support, meeting global regulatory requirements.

2.3 Quality of Battery Cells and Materials

Battery performance starts with cell selection. High-quality medical device batteries should use:

- A-grade branded cells

- Stable chemistry such as NMC or LiFePO4

- UL-listed cell suppliers

- Flame-retardant housings

- Heat-resistant wire and connectors

- Medical-grade PCBs

Avoid manufacturers using recycled or lower-grade cells, as these significantly increase safety risks.

2.4 Advanced BMS (Battery Management System)

A medical battery without a reliable BMS is unsafe.

A qualified BMS should include:

- Over-charge / over-discharge protection

- Over-current protection

- 단락 보호

- Temperature protection

- SOC and SOH monitoring

- Data logging

- Communication protocols (UART / CAN / SMbus)

다음과 같은 제조업체 동관 이잔 전자 develop intelligent BMS platforms tailored for medical use to ensure precise power management and maximize battery life.

2.5 Manufacturing Standards and Factory Capabilities

Ask the manufacturer the following:

Does the factory have:

- Automated cell sorting equipment?

- Laser welding machines?

- Welding QC systems?

- Full-process traceability?

- Aging and cycling test rooms?

- Vibration, drop, and thermal shock test equipment?

Do they follow:

- ISO9001 quality management

- ISO13485 medical device quality compliance

- 100% functional testing

- Batch traceability

A professional medical battery manufacturer should be able to guarantee every pack is built with consistency and zero defects.

2.6 R&D and Customization Ability

For medical equipment brands, customization is often essential.

Evaluate whether the manufacturer can provide:

- Custom battery pack design

- Custom electronics and firmware

- Custom molds and structural components

- Custom communication systems

- Medical-grade reliability calculations

동관 이잔 전자 has a skilled R&D team. They can design custom power solutions for medical device makers worldwide.

2.7 Long-Term Supply Stability

Many medical projects have long product cycles—5 to 10 years or more.

Choose a manufacturer that offers:

- Long-term cell supply consistency

- Stable procurement channels

- Mature production systems

- Scalability for mass production

Avoid small or unstable suppliers that may disappear or change materials unexpectedly.

2.8 After-Sales Support and Global Service

Medical equipment companies need strong after-sales support:

- Technical teams that respond quickly

- Transparent quality reporting

- Replacement and repair guarantee

- Firmware update support

- Battery lifecycle monitoring

A reliable manufacturer acts as a technology partner—not just a supplier.

3. Why Dongguan Yizhan Electronics Technology Co., Ltd. Is a Trusted Medical Lithium Battery Partner

Dongguan Yizhan Electronics is a top lithium battery pack maker. We focus on custom solutions and are a trusted supplier for many global medical device brands.

3.1 Over a Decade of Medical Battery Experience

The company has supported a wide range of medical products, including:

- Portable monitors

- Ventilators and CPAP devices

- Electrotherapy and physiotherapy equipment

- Mobile imaging devices

- Smart nursing equipment

3.2 Complete Certification Capabilities

Yizhan’s batteries comply with:

- UN38.3

- IEC62133

- UL2054 / UL1642

- CE / CB

- RoHS / REACH

3.3 Intelligent BMS Development

The company’s in-house BMS technology offers:

- Multi-layer protection

- CAN / UART / SMbus communication

- SOC accuracy optimization

- Charge cycle memory

3.4 Strict Quality Control

Manufacturing processes include:

- A-grade cell selection

- Fully automated welding

- 100% testing before shipment

- Multiple aging cycles

- Vibration, drop, and temperature tests

3.5 Custom Engineering for Medical Brands

이잔이 제공합니다:

- Rapid prototyping

- Small-batch trial production

- Custom housing design

- Engineering samples

- Full documentation for global compliance

3.6 Long-Term Stability

The company maintains long-term partnerships with major cell manufacturers and supports consistent supply for 5–10-year medical projects.

4. Steps to Choose the Right Medical Lithium Battery Manufacturer

Step 1: Define Application Requirements

Clarify:

- 전압 및 용량

- Runtime needs

- Load requirements

- Size constraints

- Communication protocol

Step 2: Evaluate Manufacturer’s Medical Experience

Check if they have done similar projects.

Step 3: Review Certifications

Ensure they can provide valid reports.

Step 4: Assess Engineering Capabilities

Look for strong R&D and BMS design capability.

Step 5: Audit the Factory

Review:

- Production equipment

- Quality control

- Testing lab

- Clean workshop

Step 6: Request Samples and Test Internally

Test for:

- Thermal stability

- 주기 수명

- Communication reliability

- Mechanical durability

Step 7: Check Long-Term Supply Strength

Confirm their cell suppliers and production scale.

Step 8: Evaluate Communication & Support

Good communication is essential for medical projects.

결론

Choosing a medical device lithium battery manufacturer is a critical decision that affects product safety, reliability, compliance, and long-term business success. With strict requirements in safety, certifications, engineering design, and reliability verification, medical battery suppliers must offer far more than standard battery pack manufacturers.

Medical device companies can find a trustworthy long-term partner. They should consider a supplier’s medical experience. They should also look at the supplier’s R&D skills and certifications. Additionally, production technology and quality control are important factors.

동관 이잔 전자 기술 유한 공사(동관 이잔 전자 기술 유한 공사) stands out as a reliable manufacturer. It meets the needs of global medical device companies. They provide customized, compliant, and high-reliability lithium battery solutions.