With the rapid popularization of electric bicycles in the global market, users are increasingly concerned about range, safety performance, and lifespan. Among many key technologies, the Battery Management System (BMS) is widely recognized as the most critical and indispensable component of electric bicycle lithium batteries.

Without a reliable BMS, even the highest quality battery cells cannot deliver their intended performance and safety.

This article will systematically analyze the working principle and important role of the BMS in electric bicycle batteries from a practical application perspective.

Part 1. What is an Electric Bicycle Battery Management System (BMS)?

A BMS is an electronic control system installed inside the electric bicycle lithium battery pack. Its main responsibilities are:

Real-time monitoring of battery operating status

Protecting the battery to operate within safe limits

Extending the overall battery lifespan

Ensuring stable operation of the entire vehicle system

Simply put, the BMS is the “brain” and “safety manager” of the electric bicycle battery.

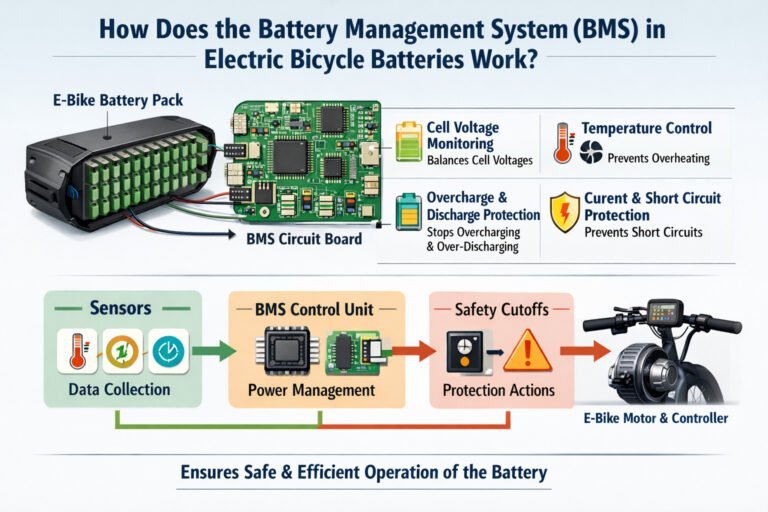

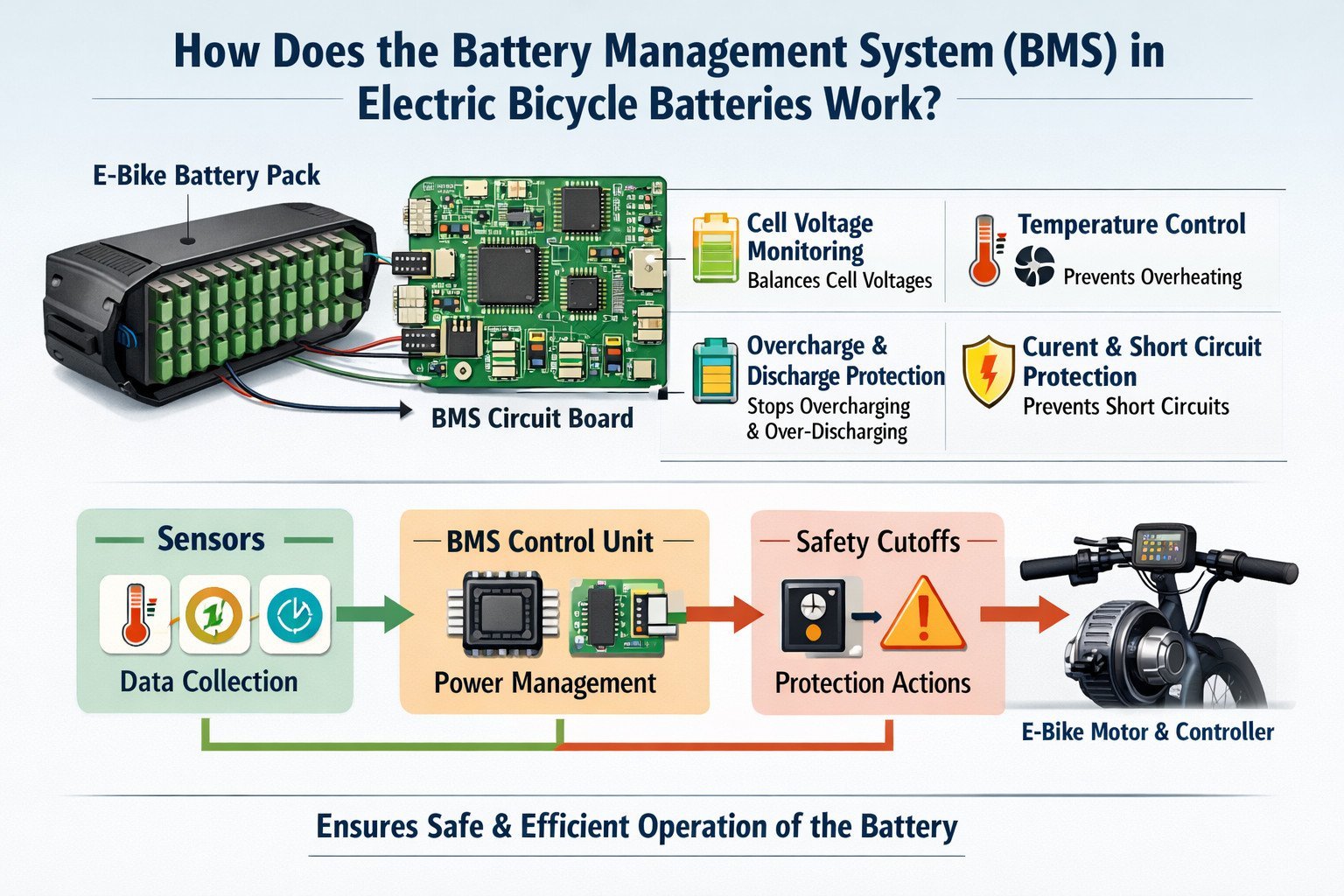

Part 2.Basic Working Principles of Electric Bicycle BMS

During battery operation, the BMS continuously manages the battery through multiple sensing and control modules, mainly including the following core aspects:

1. Voltage Monitoring and Cell Management

Electric bicycle batteries are usually composed of multiple lithium-ion cells connected in series and parallel. The BMS will:

Monitor the voltage of each cell in real time

Prevent overcharging or over-discharging of individual cells

Determine if the cell status is abnormal

When the voltage of a cell exceeds the safe range, the BMS will immediately take protective measures, such as cutting off the charging and discharging circuit.

2. Current Monitoring and Power Control

During acceleration, climbing, or high-load riding, the battery current will increase significantly. The BMS will:

Monitor charging and discharging currents in real time

Prevent overcurrent, short circuits, and other abnormal situations

Ensure stable operation of the motor and controller

This is especially important for medium-to-high power electric bicycles such as 48V and 52V.

3. Temperature Monitoring and Thermal Protection Mechanism

Temperature is an important factor affecting the safety and lifespan of lithium batteries. Through temperature sensors, the BMS:

Monitors the temperature of the cells and the inside of the battery pack

Prevents thermal runaway caused by high temperatures

Restricts unsafe charging and discharging in low-temperature environments

In electric bicycle battery design, Yizhan Electronics always considers thermal management and temperature protection as one of the core elements of its BMS solutions.

4. Cell Balancing

Due to manufacturing and usage differences, individual battery cells may experience voltage inconsistencies during long-term use.

The BMS uses a balancing function to:

Adjust individual cell voltage differences

Prevent “weak cells” from affecting the entire battery pack

Extend the lifespan of the entire battery pack

This is a key technology for ensuring stable long-term battery output.

5. State Judgment and Protection Execution

The BMS intervenes immediately when it detects the following abnormal conditions:

과다 청구

과다 방전

과전류

단락 회로

High or low temperature anomalies

By controlling execution components such as MOS transistors, the BMS can quickly cut off the circuit, preventing battery damage or safety accidents.

Part 3.Advanced Applications of Smart BMS in Electric Bicycles

As the trend towards smart electric bicycles intensifies, the functions of BMS are constantly being upgraded.

The smart BMS functions supported by Yizhan Electronics include:

Precise SOC (State of Charge) estimation

Bluetooth communication and data reading

Communication with the vehicle control system (CAN / UART)

Operating data recording and analysis

These functions not only enhance the user experience but also provide a technical foundation for brand customers to create differentiated, high-value-added products.

Part 4. The Importance of BMS for Electric Bicycle Battery Safety

In practical applications, most battery safety problems are related to management failures, not the cells themselves.

High-quality BMS can effectively:

Reduce the risk of fire, swelling, etc.

Extend battery cycle life

Reduce after-sales and maintenance costs

Improve the reliability of the entire vehicle brand

Yizhan Electronics firmly believes that the design level of the BMS directly determines the safety limit of electric bicycle batteries.

Part 5. Yizhan Electronics’ BMS Design Philosophy

In electric bicycle battery projects, Yizhan Electronics always follows the following principles:

Collaborative design of BMS with battery cells and battery structure

Customized parameters based on different vehicle models and usage scenarios

All batteries undergo BMS function testing before leaving the factory

Ensuring the consistency and stability of mass-produced products

We not only provide batteries but also provide mass-producible and long-term usable battery management solutions.

결론

In today’s rapidly developing electric bicycle industry, BMS is no longer an “invisible component,” but a core technology that guarantees safety, performance, and brand value.

Yizhan Electronics will continue to deeply cultivate electric bicycle battery and BMS technology, providing safer, more reliable, and smarter energy solutions for global customers.

FAQ | Electric Bicycle Battery BMS Frequently Asked Questions

1. What is a BMS in an electric bicycle battery? Why is it essential?

BMS (Battery Management System) is the management and protection system inside the electric bicycle lithium battery. It is responsible for monitoring voltage, current, and temperature, and providing protective control in abnormal situations.

Without a reliable BMS, the battery is prone to overcharging, over-discharging, overcurrent, or overheating, directly affecting safety and service life.

2. Does the BMS affect the power output of the electric bicycle?

A properly designed BMS will not limit normal power output.

On the contrary, a high-quality BMS can stabilize current output during high-load riding (acceleration, climbing), preventing abnormal overcurrent, thereby protecting the battery and motor system and improving the overall stability of the vehicle.

3. What are the main protection functions of an electric bicycle BMS?

The BMS used in Yizhan Electronics electric bicycle batteries typically includes:

과충전 방지

과방전 방지

과전류 및 단락 보호

High and low temperature protection

Single-cell voltage monitoring and balancing

These functions collectively ensure the safe operation of the battery in various riding scenarios.

4. Why does the battery need a balancing function? How does the BMS achieve this?

Due to differences in battery cells during long-term use, the voltage may become inconsistent.

The BMS adjusts the voltage of individual cells through the balancing function, preventing premature aging or failure of a single cell, thereby extending the cycle life of the entire battery pack.

5. What is the difference between a smart BMS and a regular BMS?

Regular BMS mainly focuses on basic protection functions;

Smart BMS adds the following features:

Accurate state of charge (SOC) estimation

Data recording and analysis

Bluetooth or communication interface (optional)

Data interaction with the vehicle system

More suitable for mid-to-high-end or intelligent electric bicycle products.

6. Can the BMS be customized for different models?

Yes. Yizhan Electronics supports customizing BMS parameters based on different vehicle models, voltage platforms, motor power, and usage scenarios, including:

Charging and discharging current thresholds

Temperature protection range

Communication interface requirements

Ensuring that the BMS is highly compatible with the vehicle system.

7. Does the BMS affect battery life?

A properly designed BMS will significantly extend battery life.

Through voltage balancing, temperature management, and abnormal protection, the BMS can effectively reduce cell loss and prevent performance degradation caused by improper use.