As 锂电池 applications continue to expand across electric bicycles, electric scooters, robots, energy storage systems, and industrial equipment, performance in cold weather has become a critical concern for manufacturers, brand owners, and end users alike. Low temperatures can significantly affect battery capacity, power output, safety, and long-term lifespan if not properly managed.

This article provides a comprehensive, practical guide on how to protect lithium batteries in cold weather, covering electrochemical fundamentals, real-world risks, design strategies, charging and storage practices, and long-term maintenance recommendations.

1. Why Cold Weather Affects Lithium Batteries

Lithium batteries rely on electrochemical reactions that are highly temperature-dependent. When ambient temperature drops, several internal processes slow down simultaneously.

1.1 Reduced Ion Mobility

At low temperatures, lithium ions move more slowly through the electrolyte and between the anode and cathode. This increases internal resistance and limits the battery’s ability to deliver current efficiently.

1.2 Increased Internal Resistance

Cold conditions cause a rise in internal resistance, which leads to:

Lower available power

Voltage sag under load

Reduced acceleration and climbing ability in electric vehicles

1.3 Temporary Capacity Loss

A lithium battery may appear to “lose” capacity in winter. In most cases, this capacity is not permanently lost but temporarily inaccessible due to slowed chemical reactions.

1.4 Risk of Lithium Plating During Charging

Charging a lithium battery at low temperatures, especially below 0°C, can cause lithium ions to deposit as metallic lithium on the anode surface. This phenomenon, known as lithium plating, is one of the most serious cold-weather risks, as it can:

Permanently reduce capacity

Increase internal short-circuit risk

Accelerate battery aging

2. Common Cold-Weather Problems in Lithium Battery Applications

2.1 Electric Bicycles and Scooters

Shortened riding range

Sudden power cut-off under load

Slow or failed charging in unheated environments

Battery shutdown triggered by BMS low-temperature protection

2.2 Robots and AGVs

Reduced peak current output

Decreased operational time per charge

Performance instability during early startup

2.3 Energy Storage Systems

Lower charge acceptance

Inefficient energy release

Higher system losses in winter conditions

Understanding these issues is the first step toward effective protection.

3. Safe Operating Temperature Ranges for Lithium Batteries

While different lithium chemistries have slightly different tolerances, general guidelines apply.

3.1 Typical Temperature Ranges

Discharge:

Recommended: -10°C to 45°C

Optimal: 10°C to 30°C

Charging:

Recommended: 0°C to 45°C

Optimal: 10°C to 30°C

Charging below freezing is the most dangerous scenario and must be carefully controlled through system design and user guidance.

4. Battery Chemistry Matters in Cold Weather

Not all lithium batteries behave the same in winter.

4.1 Lithium Iron Phosphate (LiFePO4)

优势

卓越的热稳定性

降低热失控风险

循环寿命长

Limitations:

Reduced low-temperature discharge performance

Poor cold charging tolerance without heating

LiFePO4 is widely used in industrial and energy storage applications, where safety and longevity are priorities.

4.2 Ternary Lithium (NCM / NCA)

优势

更高的能量密度

Better low-temperature discharge performance

Limitations:

More sensitive to overcharge and thermal stress

Requires more advanced BMS protection

5. The Role of the BMS in Cold Weather Protection

A high-quality Battery Management System (BMS) is the first line of defense against cold-weather damage.

5.1 Temperature Monitoring

Modern BMS systems use multiple temperature sensors placed near:

Cell groups

Charge/discharge terminals

Internal hotspots

This allows real-time thermal awareness rather than relying on ambient temperature alone.

5.2 Low-Temperature Charge Protection

A properly configured BMS will:

Block charging below a defined temperature threshold

Gradually resume charging once the battery warms up

Prevent lithium plating damage

5.3 Smart Power Limiting

Instead of abrupt shutdowns, advanced BMS solutions can:

Limit discharge current in cold conditions

Maintain system stability

Protect cells while allowing partial operation

6. Structural and Mechanical Design for Cold Protection

Battery performance in winter is not only about electronics. Physical design plays a critical role.

6.1 Insulated Battery Enclosures

Well-designed housings help retain heat generated during operation. Effective insulation materials can significantly slow temperature drop during idle periods.

6.2 Internal Thermal Buffering

Using:

Foam separators

Thermal pads

Air-gap optimization

helps reduce direct exposure of cells to external cold air.

6.3 Vibration and Expansion Control

Cold temperatures cause materials to contract. Proper mechanical tolerances prevent:

Cell deformation

Weld stress

Connector fatigue

These design considerations are standard in Yizhan Electronics’ battery pack engineering process.

7. Active Heating Solutions for Extreme Cold

For applications operating below -10°C, passive insulation may not be enough.

7.1 Self-Heating Battery Systems

Self-heating batteries use internal heaters powered by the battery itself to raise cell temperature before charging or discharging.

优势

Enables safe charging below freezing

Improves winter performance consistency

Reduces permanent capacity loss

7.2 External Heating Integration

Some systems rely on:

Vehicle power systems

Grid-connected heating

Intelligent thermal controllers

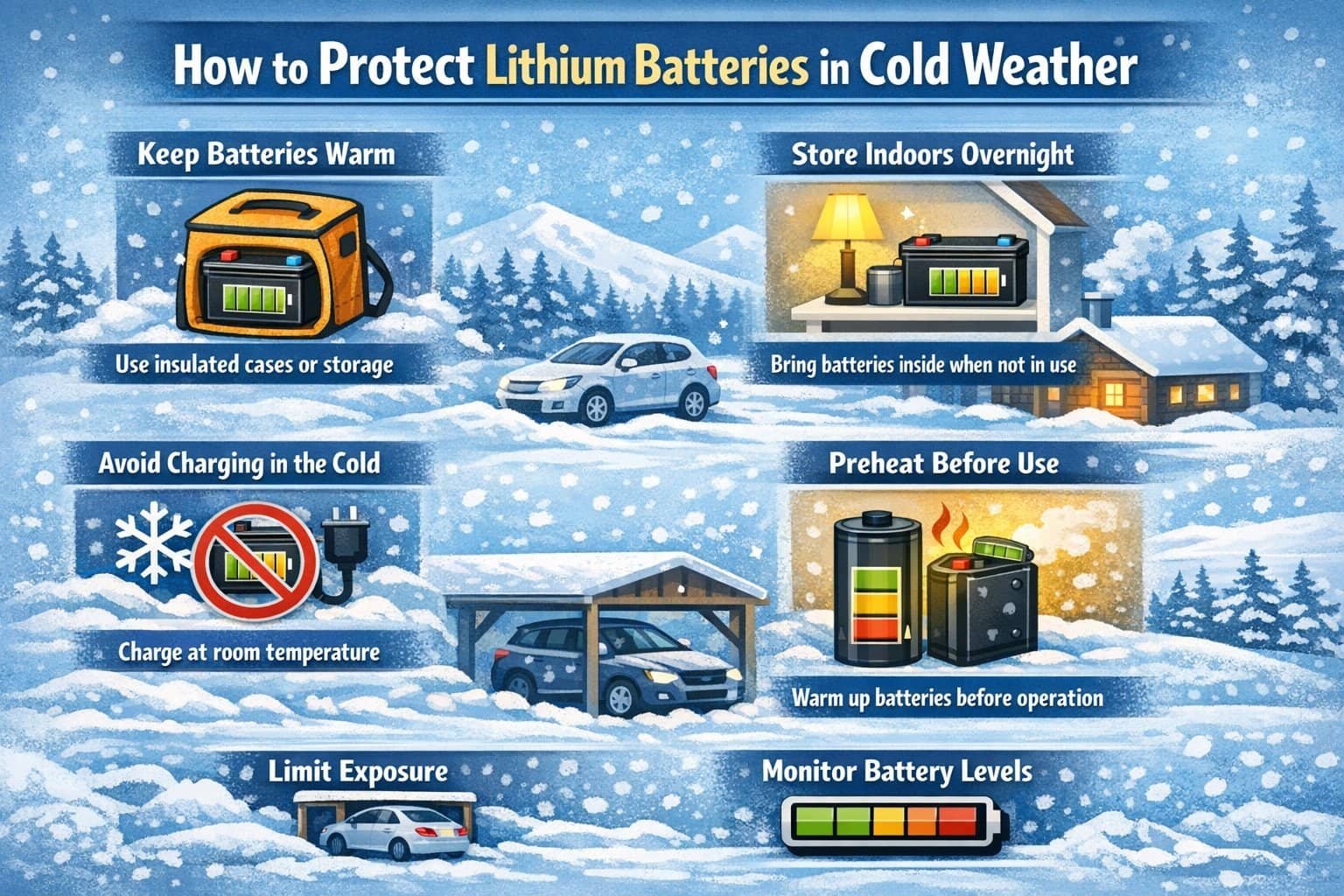

8. Proper Charging Practices in Cold Weather

User behavior plays a significant role in battery protection.

8.1 Avoid Charging in Freezing Environments

Whenever possible:

Charge batteries indoors

Allow batteries to warm up naturally before charging

8.2 Use the Correct Charger

A charger matched to the battery’s voltage, current, and BMS communication protocol ensures:

Controlled current ramp-up

Proper termination

Reduced stress in cold conditions

8.3 Let the Battery Rest After Use

After riding or operation in the cold:

Allow 30–60 minutes before charging

This stabilizes internal temperature and voltage

9. Cold-Weather Storage Recommendations

Many lithium batteries are damaged not during use, but during improper winter storage.

9.1 Ideal Storage Temperature

Recommended: 10°C to 25°C

Avoid long-term storage below 0°C

9.2 Storage State of Charge (SOC)

Ideal SOC: 40%–60%

Avoid storing fully charged or fully discharged batteries

9.3 Periodic Inspection

For long winter storage:

Check voltage every 2–3 months

Recharge if SOC drops below safe threshold

10. Long-Term Effects of Cold Exposure

Repeated cold misuse can lead to:

Permanent capacity loss

增加内部阻力

Shortened cycle life

Higher failure rates

While a single cold event may not cause immediate failure, cumulative damage is often irreversible.

11. Application-Specific Cold Protection Strategies

11.1 E-Bike and Micromobility Brands

Emphasize user education

Integrate smart BMS temperature protection

Offer insulated or removable battery designs

11.2 Industrial Equipment and Robots

Design for controlled charging environments

Integrate heating or thermal management

Prioritize stable discharge over peak power

11.3 Energy Storage Systems

Install in temperature-controlled enclosures

Use LiFePO4 with conservative charge limits

Employ system-level thermal management

12. Yizhan Electronics’ Approach to Cold-Weather Battery Design

At Yizhan Electronics, we do not treat cold weather as an afterthought. It is a core part of our battery design philosophy.

Our approach includes:

Application-specific chemistry selection

Customized BMS temperature strategies

Structural insulation and thermal optimization

Optional heating solutions

Extensive low-temperature testing and validation

We work closely with our clients to ensure their battery systems perform reliably, safely, and consistently, even in harsh winter environments.

13. Conclusion: Cold Weather Protection Is a System-Level Challenge

Protecting lithium batteries in cold weather is not about a single feature or component. It requires a holistic system-level approach that combines chemistry, electronics, structure, user behavior, and environmental understanding.

With proper design, intelligent BMS control, and correct usage practices, lithium batteries can operate safely and effectively even in demanding winter conditions.

As a professional lithium battery pack manufacturer, Yizhan Electronics remains committed to delivering reliable, climate-adapted battery solutions that power mobility, industry, and energy systems around the world, no matter the season.