With the rapid growth of the global electric bicycle market, batteries, as the core power component of eBikes, have become a key focus for international buyers in terms of performance, safety, lifespan, and supply stability. By 2026, industry standards will have further improved, and buyers will not only focus on price but also place greater emphasis on technical specifications, certification standards, customization capabilities, and long-term cooperation potential.

This article provides international buyers with a complete B2B electric bicycle battery procurement guide to help companies efficiently and safely source high-quality batteries from China.

Part 1. Electric Bicycle Battery Procurement Market Background and Trends

In recent years, global electric bicycle sales have continued to grow, with strong demand in Europe, North America, and Southeast Asia. Consumers are demanding higher standards for range, charging speed, weight, and safety, which places higher demands on the battery supply chain.

2026 procurement trends show:

Longer range and higher safety are core requirements

Users expect batteries to meet daily commuting or long-distance riding needs on a single charge, and battery stability and intelligent management functions are becoming key procurement considerations.

Increased demand for customization

Different brands have increasingly diverse needs for voltage, capacity, battery structure, and appearance design, making brand differentiation a key competitive advantage.

Higher international standards and export requirements

European EN 50604 standards, US UL standards, etc., are increasingly being listed as export thresholds, and suppliers must have a complete certification system.

Therefore, when choosing a battery supplier, buyers should not only focus on price but also on the supplier’s technical capabilities, certification qualifications, and long-term supply stability.

Part 2. Why Choose Chinese Battery Manufacturers

China has a leading global advantage in the lithium-ion battery industry chain, making it the preferred destination for B2B electric bicycle battery procurement:

Mature supply chain ecosystem

China has a complete battery industry chain, from lithium battery raw materials and cell production to BMS (Battery Management System) research and development and PACK (cell assembly) integrated solutions.

Scaled production and cost efficiency

Compared to other manufacturing countries, Chinese battery companies have lower unit production costs and higher production capacity, able to meet large-volume order demands.

International certification and export capabilities

Many Chinese manufacturers’ products have passed CE, UL, EN 50604, and other certifications, making them suitable for export to Europe, the US, and other high-standard markets. Dongguan, a major manufacturing hub, is home to a large number of professional battery companies. Among them, Dongguan Yizhan Electronics stands out as a key supplier for buyers due to its mature production capabilities, years of industry experience, and comprehensive certification system.

Part 3. How to Evaluate Suppliers

In Chinese B2B procurement, supplier evaluation is crucial for ensuring product quality and smooth cooperation. Here are four key areas that buyers should focus on:

1. Company Qualifications and Industry Experience

Factory scale and production capacity

Whether certified by international quality management systems such as ISO and IATF

Whether possessing a stable supply chain and export experience

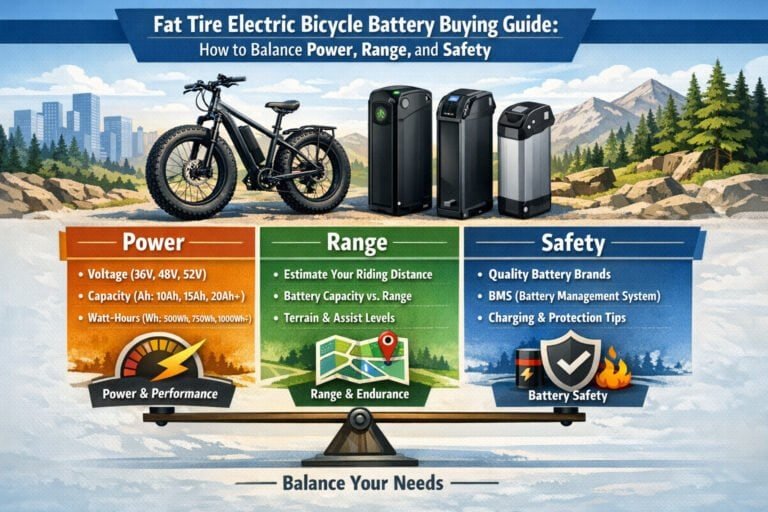

2. Product Quality and Performance Indicators

High-quality batteries directly impact vehicle performance and customer satisfaction. Buyers need to pay attention to the following indicators:

Voltage and capacity specifications: 36V, 48V, 20Ah, 30Ah, etc.

Cell brand and source: Samsung, LG, CATL, and other international first-tier suppliers

Cycle life and reliability: Number of charge and discharge cycles and life stability

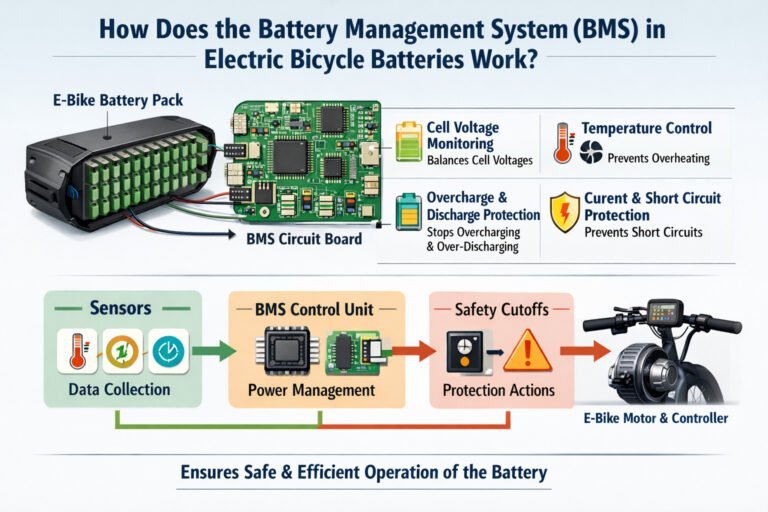

Intelligent BMS functions: Overcharge and over-discharge protection, short-circuit protection, temperature monitoring, etc.

3. Customization Capabilities (OEM/ODM)

Brand differentiation is a key factor in B2B procurement. Excellent suppliers should support:

Customized voltage and capacity configurations

Different form factor designs (down tube battery, in-tube battery, rear rack battery)

Private label branding and packaging support

Technical consulting and design services

Part 4. Safety and Certification

Safety is at the core of procurement decisions. Exported battery products must have:

EN 50604 (European electric vehicle battery safety standard)

UL, CE, RoHS and other international certifications

Lithium battery transportation certifications: UN38.3, MSDS, etc.

Suppliers with certifications not only reduce market risks but also ensure the safety and reliability of products during transportation and use.

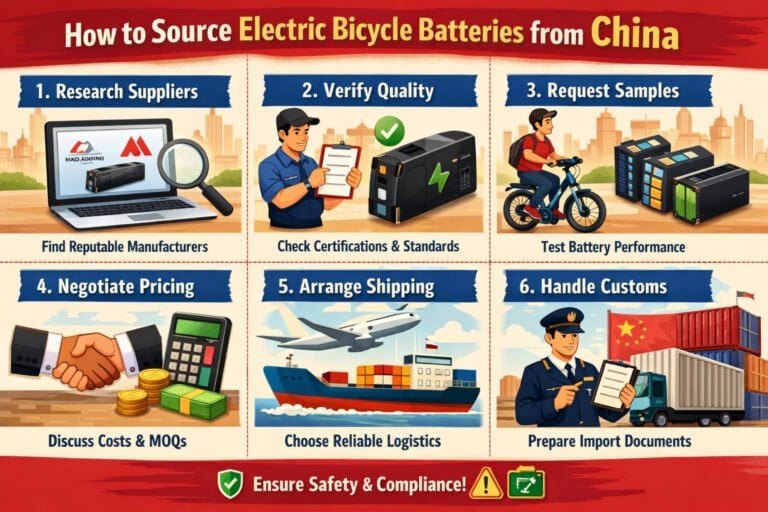

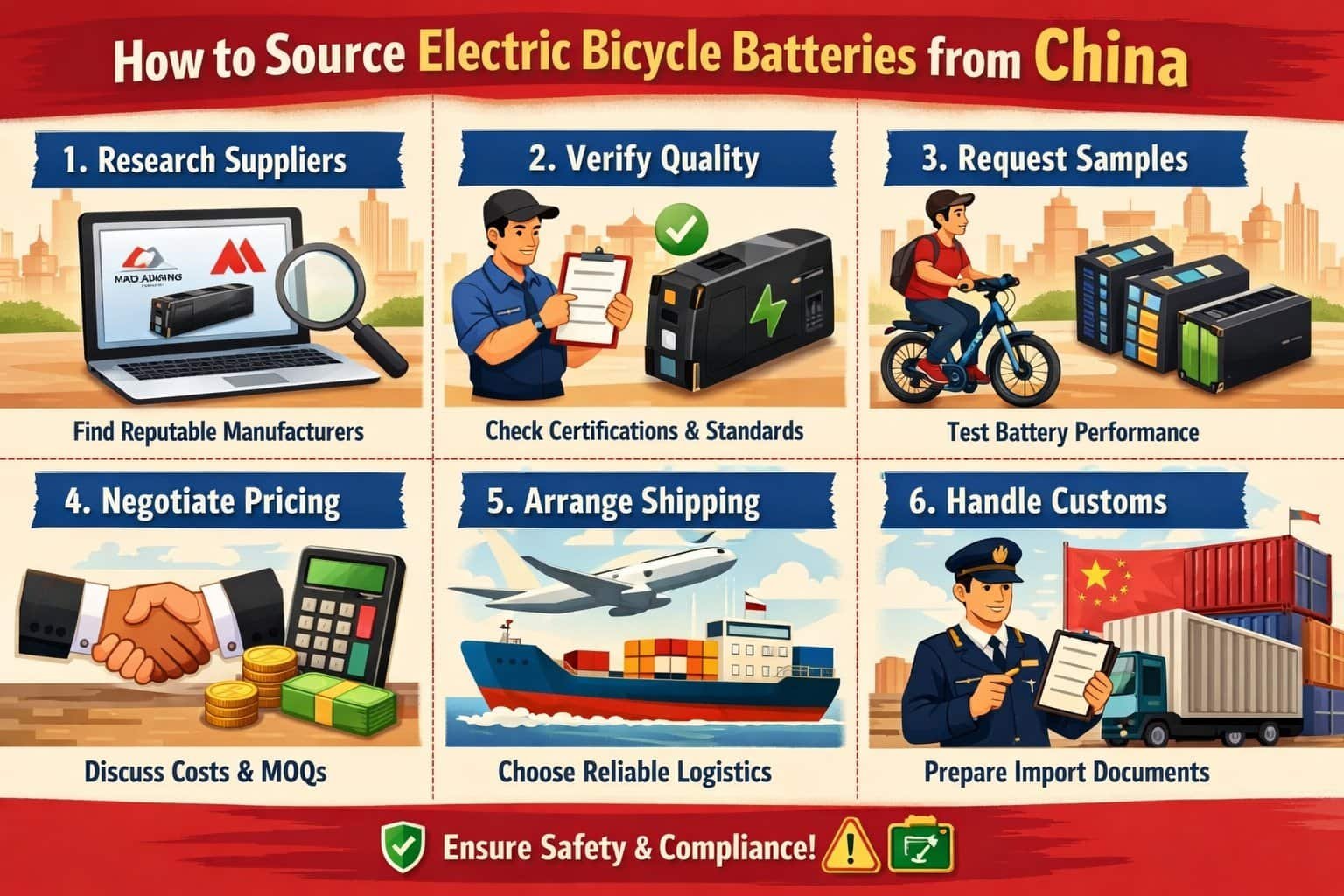

Detailed B2B Procurement Process

Successful procurement is not only about choosing a supplier, but also about a standardized process:

Initial Contact and Requirements Communication

Clarify battery specifications, certification requirements, delivery time, and budget.

Sample Evaluation

Request samples and conduct performance, appearance, and safety tests.

Contract Signing and Payment Terms

Clarify MOQ (Minimum Order Quantity), price, payment methods (T/T, letter of credit, etc.), and warranty terms.

Production and Quality Monitoring

Third-party factory audits or batch sampling can be used to ensure production transparency and stable quality. Logistics and Customs Clearance

Lithium batteries are classified as dangerous goods, and their export requires complete customs declaration documents, dangerous goods labels, and transportation documents.

Part5. Procurement Risks and Precautions

Avoid uncertified suppliers: Uncertified products may lead to customs clearance failures or market complaints.

Battery cell quality risks: Low-quality battery cells may result in short cycle life, unstable performance, or safety hazards.

Logistics and dangerous goods management: Lithium battery transportation must strictly adhere to international standards such as UN38.3.

China possesses the world’s most mature battery industry chain and a large number of professional manufacturing enterprises. By clearly defining procurement standards, supplier evaluation, and standardized procurement processes, B2B buyers can significantly improve efficiency and product quality. Dongguan Yizhan Electronic Technology Co., Ltd., with its complete production capabilities, intelligent BMS technology, international certifications, and customized services, is an important partner for overseas brands entering the global market.

Procurement suggestions: Prepare procurement documents, clarify certification and customization requirements, request samples for testing, and establish long-term cooperative relationships.

FAQ (Frequently Asked Questions)

Q1: Why choose a Chinese electric bicycle battery supplier?

Answer: China has a mature supply chain, low production costs, stable quality, and many companies possess international certifications and export capabilities.

Q2: How to determine the safety of a battery?

Answer: Check if the battery has passed certifications such as EN50604, UL, CE, and RoHS, and pay attention to the BMS intelligent protection function.

Q3: What does OEM/ODM customization service include?

Answer: Battery specifications, voltage capacity, casing design, brand labeling, packaging, and technical consulting services.

Q4: What logistics and certification requirements should be considered before procurement?

Answer: Lithium batteries are classified as dangerous goods, and export requires UN38.3, MSDS documents, and correct labeling.

Q5: How to ensure the reliability of a long-term supplier?

Answer: Evaluate company qualifications, factory scale, production process transparency, sample testing, and customer feedback.