Light electric vehicles (LEVs) are becoming more popular. This includes e-bikes, e-scooters, and hoverboards. Because of this, battery safety is crucial.

Regulatory compliance is also a key focus for buyers. UL2271 certification is one of the most important safety standards for lithium-ion battery packs. This is especially true for LEV applications in the U.S. and North American markets.

For manufacturers, importers, brand owners, and OEM buyers, it is important to understand how to obtain UL2271 batteries. These batteries must be safe and compliant. This is not just a technical issue. It affects product approval, market access, brand reputation, and long-term business success.

This article offers a complete guide on buying batteries from a professional manufacturer. It explains what UL2271 is, how to find compliant batteries, what to be careful about, and answers common buyer questions.

1. What Is UL2271 and Why It Matters in Battery Procurement

UL2271 is a safety standard created by Underwriters Laboratories (UL). It is for lithium-ion battery packs used in light electric vehicles. Unlike cell-level standards, UL2271 focuses on the entire battery pack, including:

- Lithium-ion cells

- Battery Management System (BMS)

- Electrical protection circuits

- Mechanical enclosure and insulation

- Thermal and structural safety

The goal of UL2271 is to check how batteries work during normal use and possible misuse. This helps lower risks like fire, overheating, electric shock, and mechanical failure.

Why UL2271 Is Essential

UL2271 certification is increasingly required because:

- Many U.S. cities and states mandate UL-certified LEV batteries

- Major e-commerce platforms request UL2271 documentation

- Retailers and distributors use UL2271 as a supplier qualification threshold

- Insurance providers and regulators favor UL-certified products

From a procurement standpoint, UL2271 is no longer optional—it is a market access requirement.

2. Understanding “Safe and Compliant” UL2271 Batteries

A battery that is truly safe and compliant must meet both technical and documentation requirements.

Safety Compliance Includes

- Proper cell selection with stable chemistry

- Robust BMS design with accurate protection logic

- Mechanical protection against vibration, shock, and impact

- Thermal management and insulation design

- Consistent manufacturing and quality control

Regulatory Compliance Includes

- Valid UL2271 certification for the exact battery model

- Correct labeling and traceability

- Alignment with the latest applicable UL2271 standard version

- No unapproved changes to cells, BMS, or structure after certification

Procurement teams must evaluate both aspects simultaneously.

3. Step-by-Step Guide to Procuring UL2271-Compliant Batteries

Step 1: Clearly Define Application and Technical Requirements

Before contacting suppliers, buyers should clearly define:

- End-use application (e-bike, scooter, LEV, industrial device)

- Voltage, capacity, and energy requirements

- Physical size and mounting constraints

- Environmental conditions (temperature, vibration, moisture)

- Expected lifecycle and warranty expectations

Clear specifications reduce the risk of mismatched certification or unsuitable designs.

Step 2: Identify Qualified UL2271 Battery Manufacturers

Not all battery suppliers are UL2271-capable manufacturers. Focus on companies that:

- Design and manufacture battery packs in-house

- Have prior UL2271 certification experience

- Understand BMS safety architecture

- Can provide complete documentation packages

A reliable manufacturer should be able to explain how the battery passed UL2271 testing—not just show a certificate.

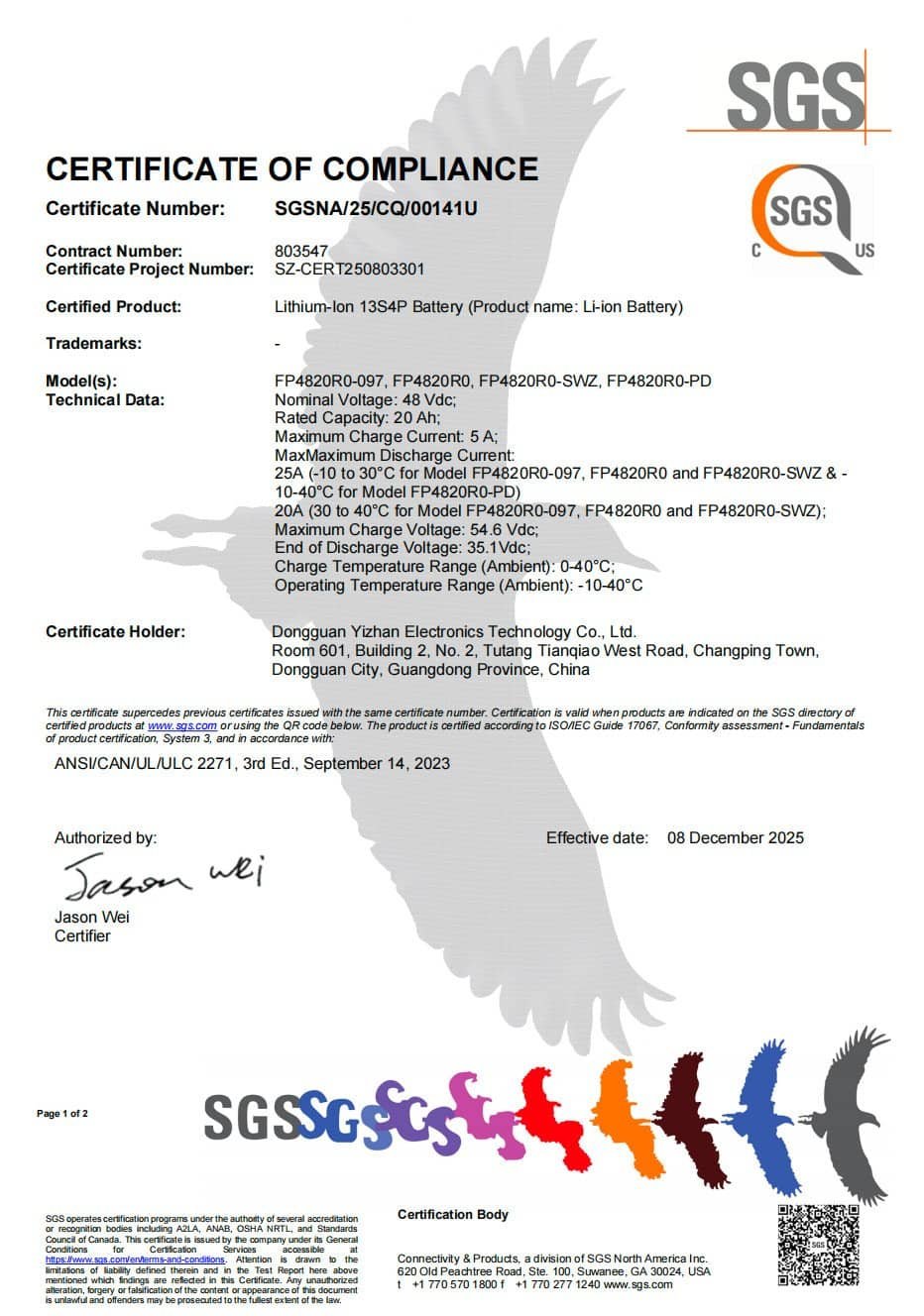

Step 3: Request Complete UL2271 Documentation

A compliant supplier should provide:

- UL2271 certificate with certificate number

- Full UL test report summary

- Battery model numbers covered by the certification

- Standard version used for testing

- Label artwork or photos showing UL markings

Partial or unclear documentation is an early warning sign.

Step 4: Verify Certification Authenticity

Procurement teams should never rely solely on PDF documents. Best practice includes:

- Cross-checking certificate numbers in UL’s official database

- Confirming that the battery model and revision match the certificate

- Ensuring no unauthorized design changes were made after certification

Verification protects buyers from false or misused UL claims.

Step 5: Sample Evaluation and Quality Validation

Even with UL2271 certification, sample evaluation is essential:

- Inspect labeling, enclosure quality, and workmanship

- Verify BMS functionality and protection behavior

- Conduct compatibility tests with the target device

- Perform basic environmental or stress testing if needed

Certification does not replace engineering validation—it complements it.

Step 6: Contractual and Supply Chain Safeguards

To ensure long-term compliance, procurement contracts should clearly define:

- Responsibility for maintaining UL2271 compliance

- Obligations if certification becomes invalid

- Change notification requirements for cells or BMS

- Warranty and liability clauses related to safety compliance

Strong contracts help manage compliance risks over the product lifecycle.

4. Key Risks to Avoid When Procuring UL2271 Batteries

Risk 1: Confusing UL2271 with Other Standards

Commonly misunderstood standards include:

- UL2271: Battery pack safety for LEVs

- UL2849: System-level e-bike safety

- UL1973: Industrial and stationary batteries

- UN38.3: Transportation safety

Only UL2271 specifically certifies LEV battery packs.

Risk 2: Assuming Cell Certification Equals Pack Certification

Cell-level certifications do not automatically make a battery pack UL2271 compliant. You must test the assembled battery, including the BMS and enclosure, as a complete system.

Risk 3: Certification Invalidated by Design Changes

UL2271 certification applies to a specific design configuration. Changes in:

- Cell brand or model

- BMS hardware or firmware

- Mechanical housing

- Wiring or insulation materials

may invalidate certification and require re-testing.

Risk 4: Expired or Outdated Standard Versions

While UL certificates do not always “expire,” they can become outdated if:

- The UL2271 standard is revised

- Regulatory expectations change

- Follow-up inspections are not maintained

Procurement teams should periodically re-verify compliance status.

5. Frequently Asked Questions (FAQ)

Q1: What products require UL2271 batteries?

UL2271 applies primarily to light electric vehicles, including e-bikes, e-scooters, hoverboards, and similar personal mobility devices using lithium-ion battery packs.

Q2: Is UL2271 mandatory worldwide?

UL2271 is not globally mandatory, but the U.S. and North American markets strongly require or expect it. Many international buyers adopt UL2271 voluntarily as a high-level safety benchmark.

Q3: Does UL2271 certification guarantee zero risk?

No certification can eliminate all risk. UL2271 greatly lowers safety risks by checking performance in set test conditions. However, proper system setup and use are still crucial.

Q4: Can one UL2271 certificate cover multiple battery models?

Only if the certification scope includes the models and they share identical safety-critical designs. Otherwise, you must obtain separate certification or evaluation.

Q5: How long does UL2271 certification take?

The timeline can change based on design readiness and test results. It usually takes several weeks to a few months. This includes testing and reviewing documentation.

Q6: What happens if a UL2271 battery fails in the field?

Contractual terms, root-cause analysis, and the product’s use within certified conditions determine responsibility. This is why supplier capability and after-sales support matter.

Q7: Is UL2271 enough for selling batteries online?

Some platforms may require additional certifications or documentation. UL2271 addresses safety, but transport, EMC, and local compliance may also apply.

Q8: How often should we recheck UL2271 compliance?

Best practice is to re-verify annually or whenever there are design changes, supplier changes, or regulatory updates.

6. Best Practices for Long-Term UL2271 Battery Procurement

For sustainable sourcing, companies should:

- Establish an internal UL certification tracking system

- Work with manufacturers experienced in compliance maintenance

- Schedule periodic supplier audits

- Combine UL2271 with robust internal quality control

- Treat battery safety as a strategic partnership, not a one-time purchase

This approach reduces long-term operational and regulatory risks.

7. Conclusion

Procuring safe and compliant UL2271 batteries is a structured process that combines technical understanding, documentation verification, supplier evaluation, and long-term compliance management.

For global buyers and OEM partners, choosing the right UL2271 battery supplier means:

- Enhanced product safety

- Easier market entry

- Reduced regulatory and liability risks

- Stronger brand credibility

At Yizhan Electronic Technology Co., Ltd., we focus on battery safety and compliance at every stage. This includes design, testing, manufacturing, and delivery. We provide customers with reliable battery solutions that are ready for the market.

In a market where safety defines success, UL2271-compliant procurement is not just a requirement—it is a competitive advantage.