As electrification speeds up in many industries, the need for safe and efficient lithium battery packs is growing. This includes eBikes, AGVs, robotics, medical devices, communication equipment, and energy storage.

Customizable battery packs are also in high demand. For global brands, OEMs, and equipment manufacturers, choosing a reliable lithium battery solution provider is no longer just an operational decision. It is a strategic investment that directly influences product safety, performance, lifecycle cost, and end-user satisfaction.

China has many battery manufacturers. The challenge is finding a partner. You need someone who is professional, trustworthy, and can offer stable long-term support.

This article provides a comprehensive guide to help overseas buyers evaluate lithium battery suppliers effectively.

1. Why Choosing the Right Battery Supplier Matters More Than Ever

A lithium battery is more than just a part. It is the “power system” that affects how reliable a device is. A poor-quality battery may result in:

- reduced cycle life

- expansion or swelling

- overheating

- communication errors

- shortened mileage or runtime

- severe safety issues such as thermal runaway

In industries like medical electronics, mobility devices, scooters, AGVs, and robotics, picking the wrong supplier can cause recalls. This can harm your reputation and lead to financial losses.

Choosing a skilled, experienced, and well-managed supplier is crucial for product success and long-term growth.

2. Key Criteria to Evaluate a Lithium Battery Solution Provider

To ensure safety, stability, and performance, buyers should evaluate suppliers based on the following critical criteria:

(1) Manufacturing Experience and Specialization

A reliable supplier should have many years of experience in battery pack engineering, manufacturing, and BMS development.

Questions to ask:

- How many years has the company been producing custom battery packs?

- Do they specialize in your industry?

- Do they have an internal engineering team?

Experienced suppliers are more capable of avoiding common failure points such as welding weakness, unequal cell matching, inadequate insulation, and improper BMS configuration.

Yizhan Advantage:

Dongguan Yizhan Electronics Technology Co., Ltd. has more than 12 years of experience in designing and making lithium batteries. They serve customers in mobility, industrial equipment, and robotics.

(2) Strict Cell Selection & Pack Assembly Process

Quality begins with cell selection. A trustworthy supplier should only use:

- Grade-A certified cells

- reputable brands (Samsung, LG, Panasonic, CATL, EVE, etc.)

- strict internal cell matching (capacity, voltage, IR)

Ask for:

- cell batch reports

- IR/voltage matching records

- welding pull-force test data

- pack assembly photos

Yizhan Practice:

Yizhan uses 100% cell grading, laser welding, EVA cushioning, and multi-layer insulation. This ensures stability and a long cycle life.

(3) Engineering Capability and Customization Strength

A solution provider should offer:

- custom BMS development

- CAN/SMBus/UART communication protocols

- structure design and 3D modeling

- waterproof, shockproof, and heat management solutions

Yizhan Highlight:

Yizhan provides full OEM/ODM engineering services, including BMS R&D, structural optimization, mold development, and industrial-grade protection design.

(4) Compliance With International Certifications

A reliable supplier should be able to provide or support certifications such as:

- UL2271 / UL2580

- CE / RoHS

- UN38.3 / MSDS

- IEC62133 / CB

These ensure safe transportation and global compliance.

Yizhan Certification Strength:

Yizhan’s battery packs meet international standards including UL2271, EN50604, UN38.3, CE, and more.

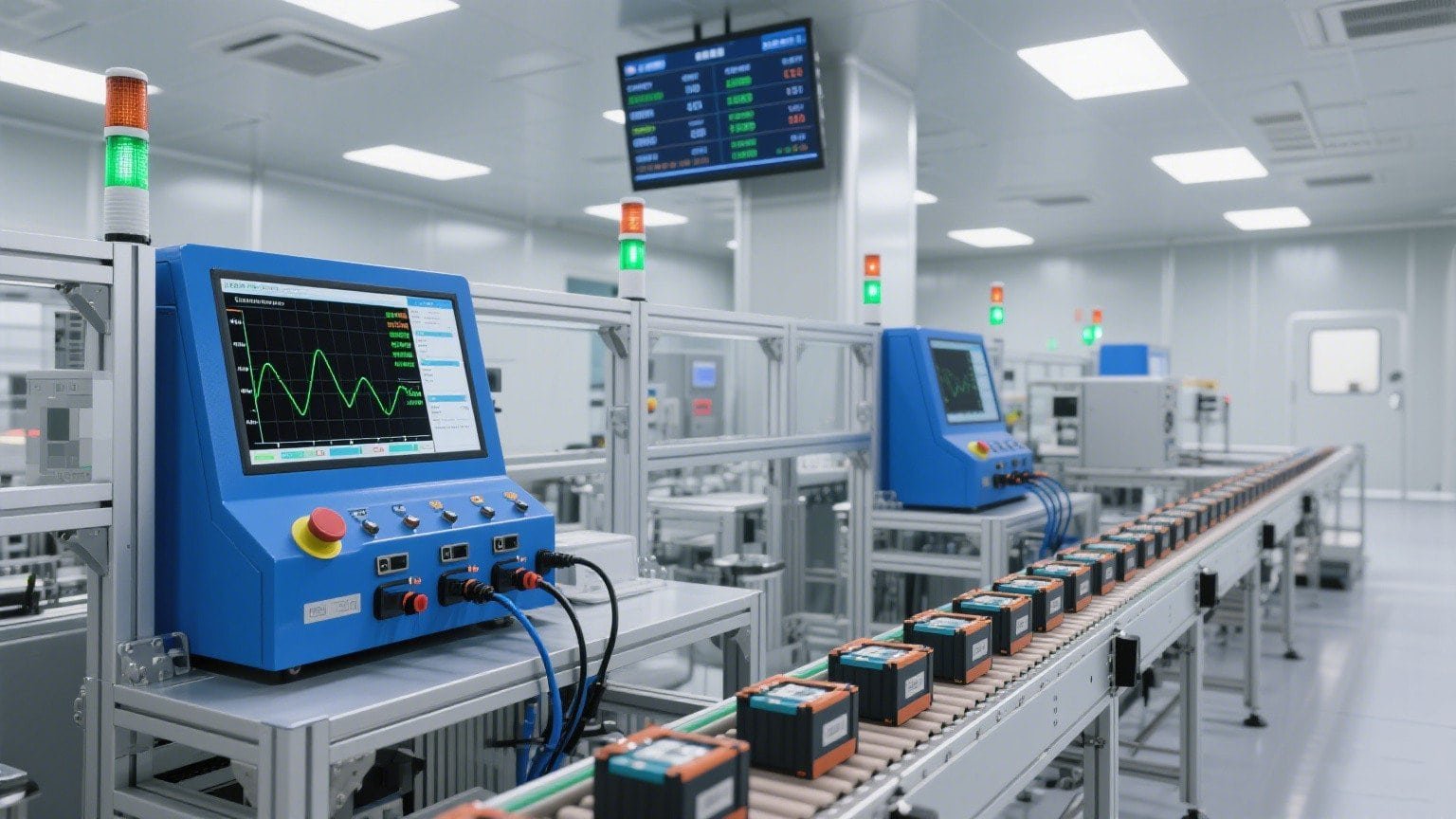

(5) Factory Facilities and Production Capabilities

A professional manufacturer should have:

- automated assembly lines

- dust-free workshops

- laser welding machinery

- aging & cycle testing cabinets

- vibration and environmental test systems

These directly determine the consistency and safety of battery packs.

Yizhan Factory Capability:

Yizhan operates advanced production lines equipped with state-of-the-art welding, testing, and inspection systems.

(6) Quality Control System & Testing Standards

Key QC processes include:

- IQC, IPQC, FQC, OQC

- 100% aging test

- cycle life test

- vibration and drop tests

- BMS communication & protection functional tests

- high/low-temperature reliability checks

Yizhan Quality Focus:

Every battery pack goes through strict quality control. This includes checking the welding, aging tests, high-temperature tests, and full-function validation before shipping.

(7) R&D Investment and Long-Term Support

A strong supplier continuously invests in:

- smart BMS

- higher energy density technology

- fast-charging solutions

- waterproofing and ruggedization

- communication protocols and data logging

Yizhan Long-Term Commitment:

With an experienced engineering team, Yizhan continues to enhance waterproof design, BMS intelligence, structural reliability, and battery performance.

(8) After-Sales Service and Technical Support

A reliable supplier must offer:

- quick engineering support

- troubleshooting guidance

- stable long-term supply

- warranty handling

- continuous improvement services

Yizhan Customer Support:

Yizhan provides one-to-one project management, engineering feedback, and long-term support for global OEM customers.

3. Common Mistakes to Avoid When Choosing a Battery Provider

❌ Selecting solely based on the lowest price

Low prices often indicate recycled cells or unqualified BMS.

❌ Not verifying factory capabilities

Some suppliers are trading companies with no in-house manufacturing.

❌ Not requesting test reports

Aging, cycle, and IR reports are essential for quality validation.

❌ Ignoring communication efficiency

Clear technical communication reflects engineering strength.

❌ Accepting incomplete documentation

Always request specs, drawings, and certifications.

4. Why Global Buyers Choose Dongguan Yizhan Electronics Technology Co., Ltd.

✔ 12+ Years of Manufacturing Experience

Serving eBike, robotics, AGV, and industrial equipment markets.

✔ Complete OEM/ODM Capability

From cell selection to BMS design, 3D structure, assembly, and testing.

✔ Robust Quality Control System

Full-process QC with strict testing standards.

✔ Professional Engineering Team

Specialists in high-safety, high-efficiency battery solutions.

✔ Rich Certification Experience

Supports UL2271, CE, RoHS, UN38.3, IEC62133, and more.

✔ Solutions for Multiple Industries

- eBikes & eScooters

- AGV & AMR

- robots & industrial machinery

- medical devices

- portable power

- communication systems

- energy storage

✔ Stable Global Supply Chain

Reliable lead times, quick sampling, and long-term consistency.

5. Steps to Work With the Right Battery Solution Provider

Step 1 — Define Requirements

Voltage, size, current, protocol, IP rating, certifications, etc.

Step 2 — Request a Full Technical Proposal

A qualified supplier will offer a complete engineering solution.

Step 3 — Evaluate Production & QC

Video audits or factory visits help confirm capability.

Step 4 — Sample Testing

Verify performance in real scenarios.

Step 5 — Move to Mass Production

Establish long-term cooperation and supply agreements.

6. Final Thoughts: Your Battery Partner Determines Your Product’s Future

The global lithium battery market is rapidly evolving. As safety regulations grow tougher and application requirements become more demanding, selecting a competent, experienced, and reliable supplier is essential.

Dongguan Yizhan Electronics Technology Co., Ltd. is committed to delivering high-quality, safe, and innovative lithium battery solutions for global customers. Yizhan has strong engineering skills, strict safety measures, and a lot of OEM/ODM experience. This makes Yizhan a trusted partner for brands around the world.