Dans les secteurs de la mobilité électrique et des énergies renouvelables, qui connaissent aujourd'hui une croissance rapide, la technologie des batteries au lithium continue de progresser rapidement. Cependant, la densité énergétique élevée et l'électrochimie complexe posent des problèmes de performance et de sécurité. C'est là qu'intervient le système de gestion de la batterie (BMS). Lorsque nous parlons d'une batterie BMS, nous parlons d'un bloc-batterie équipé d'un système intelligent conçu pour surveiller, protéger et optimiser ses performances.

Dans cet article, nous allons nous plonger dans ce qu'est une batterie BMS, comment elle fonctionne, les fonctions clés d'un BMS, ses types, et pourquoi les batteries équipées de BMS sont essentielles dans les applications modernes telles que les vélos électriques, les systèmes de stockage de l'énergie électrique et solaire, et l'automatisation industrielle.

Qu'est-ce qu'une batterie BMS ?

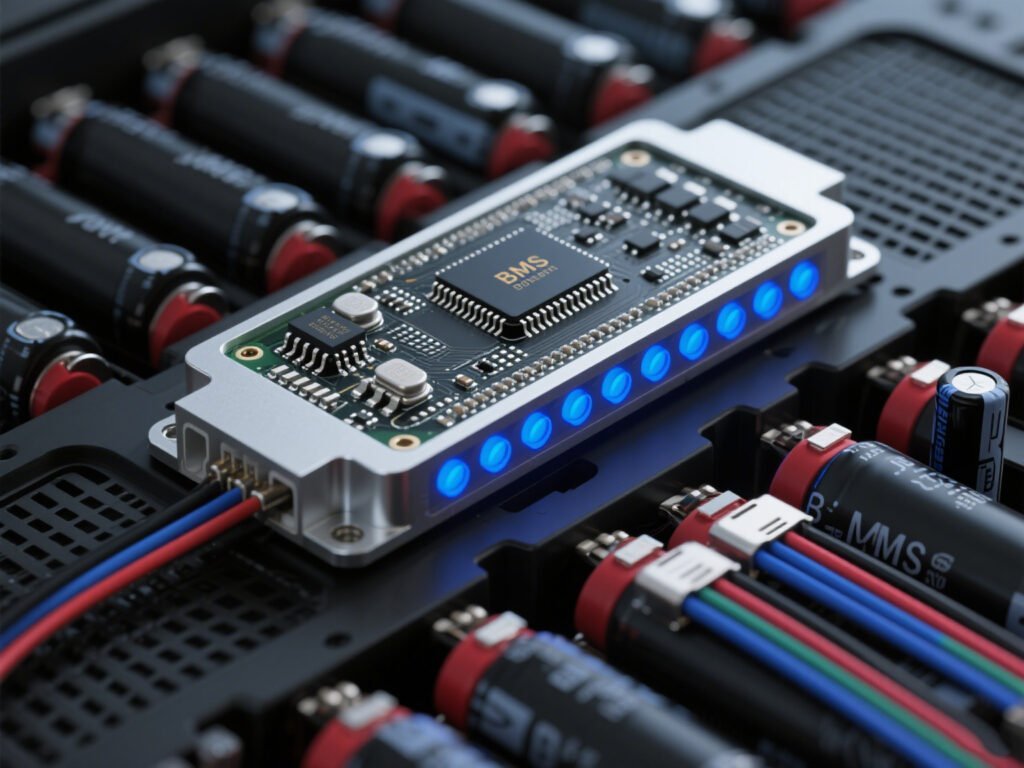

Une batterie BMS est une batterie au lithium qui intègre un système de gestion de la batterie, un système électronique intelligent qui supervise le fonctionnement de la batterie afin de garantir la sécurité, les performances et la longévité.

Par essence, un BMS agit comme le cerveau de la batterie. Il recueille et traite en permanence des données telles que :

Tension de chaque cellule

Température

État de charge (SOC)

Flux actuel

État de l'équilibrage des cellules

Détection des défauts

Sur la base de ces données, le BMS contrôle les cycles de charge/décharge, communique avec les systèmes externes (tels que les contrôleurs de véhicules ou les onduleurs) et déclenche des mesures de protection en cas de conditions anormales.

Pourquoi le BMS est-il important pour les piles au lithium ?

Contrairement aux batteries plomb-acide traditionnelles, les batteries lithium-ion sont plus sensibles à la chaleur :

La surcharge - qui peut entraîner une surchauffe, un gonflement ou même un incendie

La surcharge - qui peut endommager la batterie de façon permanente

Emballement thermique - lorsque des températures élevées provoquent des courts-circuits internes

Déséquilibre des cellules - entraînant une usure inégale et une réduction de la durée de vie de la batterie

Un BMS garantit que chaque cellule individuelle du pack fonctionne selon des paramètres sûrs. Sans BMS, les batteries au lithium pourraient devenir peu fiables ou dangereuses, en particulier dans les applications à forte consommation d'énergie ou à haute température.

Principales fonctions d'un système de gestion de la batterie

Surveillance de la tension

Le BMS suit la tension de chaque cellule individuelle et la tension globale du pack. Si une cellule dépasse le seuil de tension de sécurité pendant la charge ou descend trop bas pendant la décharge, le BMS interrompt le processus pour éviter tout dommage.

Contrôle de la température

Les capteurs thermiques mesurent la température interne et externe de la batterie. Si la température dépasse les limites, le BMS peut ralentir la charge ou arrêter la batterie pour éviter la surchauffe.

Surveillance du courant et protection contre les courts-circuits

En suivant constamment le courant, le BMS protège contre :

- Conditions de surintensité

- Court-circuit

- Inversion de polarité

Cette caractéristique est essentielle dans les applications à forte charge comme les vélos électriques ou les outils électriques.

Estimation de l'état de charge (SOC)

Le BMS calcule la charge restante de la batterie (comme une jauge de carburant pour votre batterie). Pour ce faire, il utilise des algorithmes tels que le comptage de Coulomb et l'estimation basée sur la tension.

Analyse de l'état de santé (SOH)

Le BMS suit la dégradation au fil du temps, offrant aux utilisateurs un aperçu de la durée de vie de la batterie et de son niveau de performance.

Équilibre cellulaire

Les cellules au lithium peuvent se déséquilibrer avec le temps. Le BMS redistribue activement l'énergie entre les cellules pour assurer une tension uniforme, améliorant ainsi la longévité et la capacité.

Interface de communication

Les systèmes BMS modernes sont dotés de protocoles CAN bus, UART, RS485, SMBus ou I²C pour communiquer avec des systèmes externes tels que :

- Contrôleurs de vélos électriques

- Onduleurs solaires

- Systèmes de gestion de l'énergie (EMS)

- Calculateurs pour véhicules

Types de systèmes de GTB

Il existe plusieurs architectures de systèmes de gestion des bâtiments :

- BMS centralisé

Toutes les fonctions et tous les capteurs sont logés sur une seule carte de contrôle. Ceci est courant dans les petits et moyens packs de batteries comme les vélos électriques ou les systèmes d'alimentation sans interruption.

- BMS distribué

Chaque cellule ou module possède sa propre petite unité de surveillance. Ces unités envoient des données à un contrôleur principal. Convient aux systèmes à grande échelle tels que les véhicules électriques ou les panneaux solaires.

- BMS modulaire

Une approche hybride qui combine un contrôle centralisé avec une gestion modulaire des cellules. Elle offre une grande flexibilité pour les applications de taille moyenne à grande.

Applications des batteries BMS

✅ Vélos électriques (eBikes)

Un BMS fiable garantit une charge sûre, une puissance de sortie constante et une communication en temps réel avec le contrôleur du vélo électrique. Les systèmes BMS modernes prennent également en charge le Bluetooth pour les diagnostics basés sur des applications.

✅ Mobilité électrique

Dans le domaine de la mobilité électrique, le BMS gère des milliers de cellules individuelles, garantissant des performances constantes, la sécurité et l'intégration avec les systèmes de freinage régénératif et de transmission.

✅ Systèmes de stockage d'énergie (SSE)

Pour le stockage solaire et éolien, le BMS gère des batteries au lithium à grande échelle, en maintenant la stabilité en cas de charges fluctuantes et d'apports d'énergie renouvelable.

✅ Alimentations sans interruption (ASI)

Une batterie équipée d'un BMS protège les équipements critiques en garantissant des opérations de sauvegarde de l'alimentation électrique fluides et sûres.

✅ Robotique et AGV

Les robots industriels et les véhicules à guidage automatique (AGV) s'appuient sur des batteries au lithium de haute performance avec un contrôle BMS robuste pour assurer la précision, la sécurité et un long cycle de vie.

Quelles sont les caractéristiques d'une batterie BMS de haute qualité ?

Toutes les batteries BMS ne sont pas égales. Les principales caractéristiques d'une batterie BMS fiable sont les suivantes

- Estimation précise du SOC/SOH

- Protocoles de communication à grande vitesse (CAN/UART)

- Protection thermique et de courant robuste

- Détection et enregistrement intelligents des défaillances

- Boîtier étanche ou renforcé (IP65/IP67)

- Conformité aux certifications (UN38.3, CE, EN 50604, etc.)

Tendances des batteries BMS en 2025

Le secteur des batteries évolue. Voici quelques tendances émergentes en matière de batteries BMS :

BMS alimenté par l'IA pour les diagnostics prédictifs

BMS connecté au cloud pour la surveillance à distance et la gestion de la flotte.

Smart BMS avec connectivité Bluetooth ou application mobile

Normes de sécurité de niveau automobile (ISO 26262)

Intégration aux systèmes de charge rapide (CCS, GB/T)

Une batterie BMS est plus qu'un simple pack de lithium : c'est une solution énergétique intelligente, autoprotectrice et très performante. Qu'il s'agisse d'alimenter un vélo électrique, de faire fonctionner un système d'énergie solaire ou de construire des robots autonomes, l'intégration d'un système de gestion de batterie fiable est essentielle pour maximiser l'efficacité, la sécurité et le cycle de vie.

Alors que la technologie des batteries au lithium continue d'évoluer, le rôle du BMS devient encore plus critique. Le choix d'une batterie dotée d'un BMS robuste et intelligent n'est pas seulement une question de performance, c'est une question de confiance.