Dans le domaine de la fabrication des piles au lithium, deux formats de cellules cylindriques - 18650 et 21700 - sont devenus les normes les plus largement reconnues pour les batteries de haute performance. Qu'ils soient utilisés dans des vélos électriques, des outils électriques, des systèmes de stockage d'énergie ou des véhicules électriques, ces deux types de cellules jouent un rôle crucial dans l'alimentation du monde moderne.

Toutefois, à mesure que la technologie progresse et que la demande d'une densité énergétique plus élevée augmente, les fabricants sont désormais confrontés à une décision importante : Faut-il continuer à utiliser les cellules 18650 traditionnelles ou passer aux cellules 21700 plus puissantes ?

Cet article explore les principales différences, les avantages en termes de performances, les défis de fabrication et les tendances d'application des cellules 21700 et 18650 dans la production de piles au lithium.

1. Que sont les piles 18650 et 21700 ?

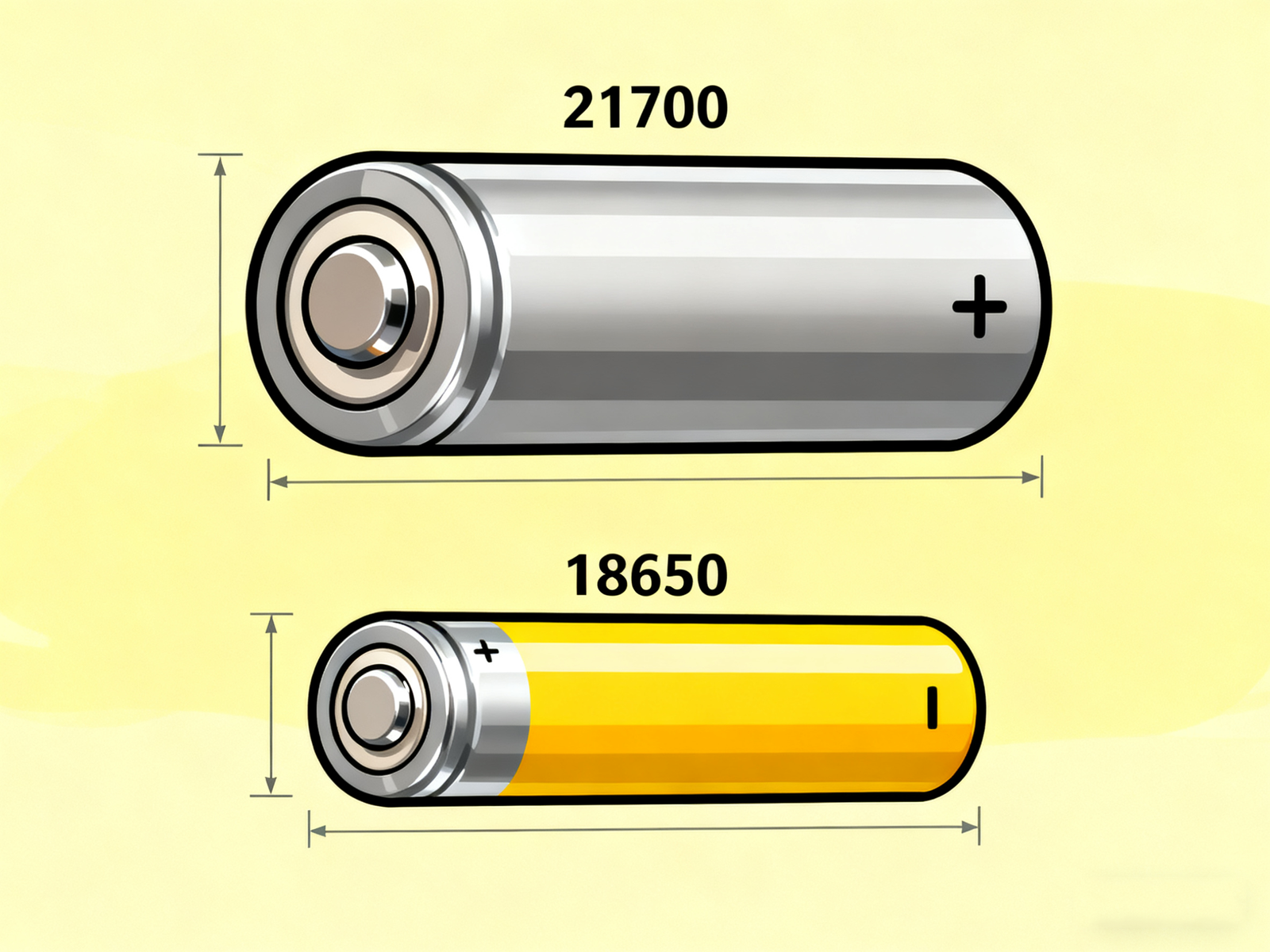

Les noms "18650" et "21700" font référence aux dimensions physiques des cellules lithium-ion cylindriques :

- Cellule 18650 : 18 mm de diamètre, 65 mm de longueur.

- Cellule 21700 : 21 mm de diamètre, 70 mm de longueur.

Il s'agit dans les deux cas de batteries lithium-ion cylindriques, utilisant généralement des matériaux de cathode tels que LiCoO₂ (LCO), NCM/NCA ou LiFePO₄ (LFP). Cependant, l'augmentation de la taille des batteries de 18650 à 21700 permet des gains substantiels en termes de capacité énergétique et d'efficacité.

2. Comparaison de la capacité et de la densité énergétique

Un élément 21700 offre généralement une capacité supérieure de 35-50% à celle d'un élément 18650. Par exemple, dans les batteries de vélos électriques ou les modules de stockage d'énergie, il faut moins d'éléments 21700 pour obtenir la même capacité, ce qui simplifie la conception du pack et réduit le nombre de soudures et de connexions.

Une densité énergétique plus élevée signifie également une plus longue durée de fonctionnement et une meilleure autonomie, ce qui fait de la cellule 21700 un choix privilégié pour les VE de la prochaine génération et les vélos électriques haut de gamme.

3. Performance thermique et gestion de la chaleur

La gestion thermique est un facteur crucial dans la conception des batteries au lithium. Bien que les cellules 21700 stockent plus d'énergie, leur taille plus importante signifie également une plus grande accumulation de chaleur si elles ne sont pas gérées correctement.

Les techniques de fabrication modernes telles que le soudage de précision, le groupement équilibré des cellules et l'optimisation du BMS peuvent compenser cet inconvénient.

4. Résistance interne et efficacité

Les cellules 21700 se caractérisent généralement par une résistance interne plus faible grâce à une conception améliorée des électrodes et à des matériaux avancés. Une résistance plus faible permet non seulement d'améliorer le taux de décharge, mais aussi d'augmenter la vitesse de charge, un avantage très apprécié dans les applications de mobilité électrique.

5. Considérations relatives à la fabrication et aux coûts

Les cellules 18650 sont produites en masse depuis plus d'une décennie, ce qui a permis de mettre en place des lignes de production matures et de réduire les coûts. Les cellules 21700, bien que plus récentes, rattrapent rapidement leur retard grâce à l'augmentation des capacités de production des principaux fabricants.

6. Conception structurelle et efficacité de l'espace

Les cellules 21700 étant plus grandes, le nombre de cellules par module diminue, ce qui simplifie la construction des boîtiers. Toutefois, dans les applications où l'espace est limité ou qui présentent des contraintes de conception spécifiques, comme les scooters électriques compacts ou les équipements médicaux, les petites cellules 18650 restent mieux adaptées.

7. Scénarios d'application

Les cellules 18650 et 21700 ont toutes deux des applications bien établies, mais leurs cibles industrielles diffèrent légèrement. Le 18650 reste le choix le plus courant pour les appareils sensibles au coût et limités en espace, tandis que le 21700 domine les secteurs à haute performance.

8. Conception de l'ensemble des batteries et optimisation du système de gestion de la batterie

Le passage des cellules 18650 à 21700 nécessite une nouvelle conception de l'agencement du module de batterie et l'optimisation des algorithmes du BMS. Avec moins de cellules, l'équilibrage de la tension et la surveillance de la température deviennent plus faciles à gérer, ce qui améliore les performances globales du système.

9. Facteurs environnementaux et de durabilité

Moins de cellules par pack signifie moins de consommation de matériaux et moins de déchets. La densité énergétique plus élevée des cellules 21700 favorise les produits à haut rendement énergétique et contribue à réduire les émissions de carbone.

10. Défis liés à la transition vers les cellules 21700

Le passage au 21700 nécessite de moderniser les équipements, de garantir l'uniformité thermique et d'adapter les chaînes d'approvisionnement. Toutefois, ces défis sont rapidement surmontés grâce à l'innovation industrielle.

11. Tendances du marché et perspectives d'avenir

Le marché mondial des piles au lithium évolue vers une densité énergétique plus élevée, un contrôle plus intelligent et une chimie plus sûre. Le 21700 et les formats plus récents comme le 4680 remplaceront progressivement le 18650 dans les applications de grande capacité, tandis que le 18650 continuera à servir pour les appareils plus petits.

Les cellules 18650 et 21700 présentent toutes deux des atouts uniques. Le 18650 offre une fiabilité et une rentabilité éprouvées, tandis que le 21700 offre une densité énergétique supérieure et une conception simplifiée. Pour des fabricants comme Dongguan Yizhan Electronics Technology Co. Ltd, la maîtrise des deux technologies garantit des solutions de batteries personnalisées et de haute qualité pour diverses applications mondiales.