With the widespread use of electric bicycles in urban commuting, food delivery, and recreational riding, battery range, lifespan, and safety and stability have become one of the core concerns for both users and brands.

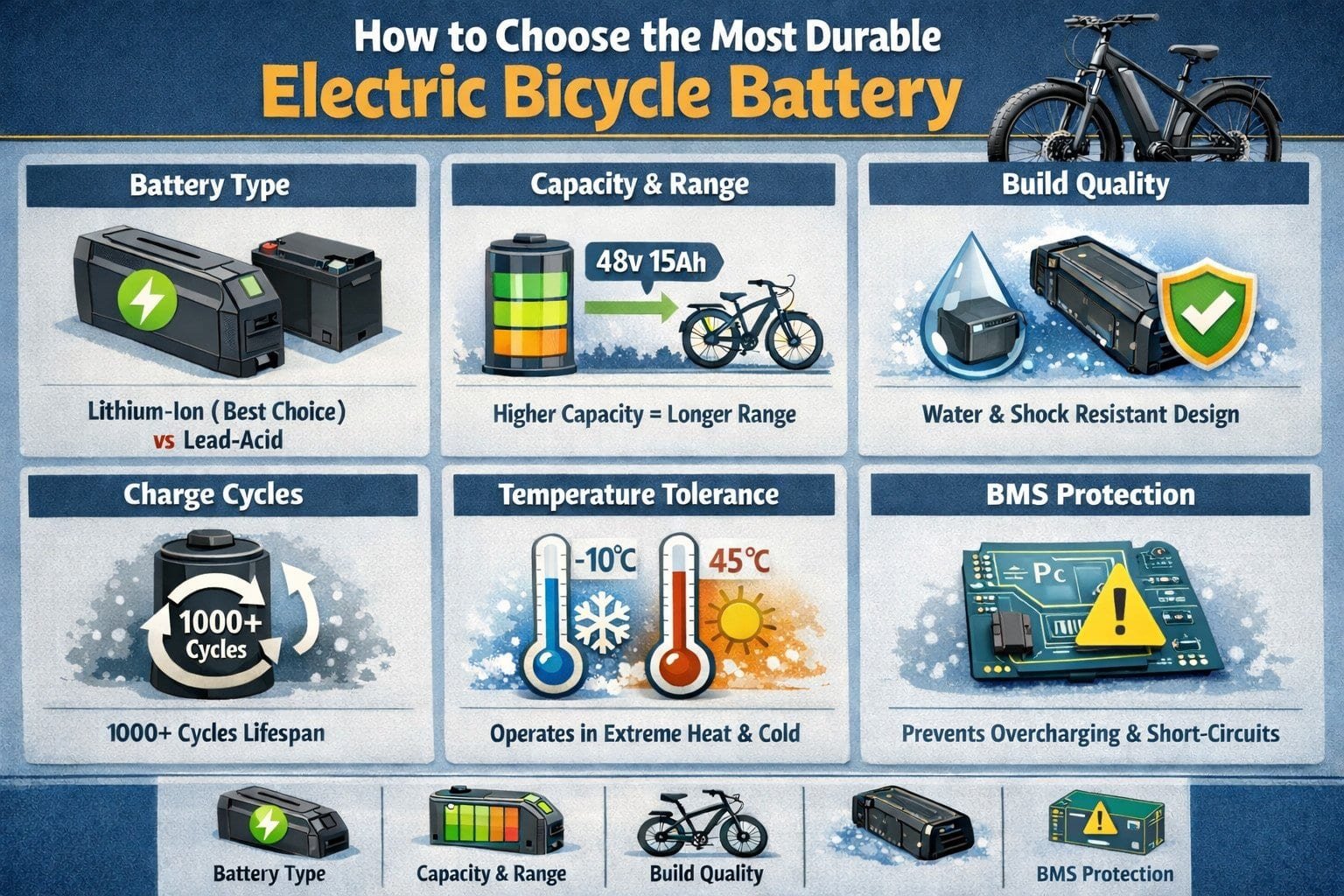

A truly “durable” electric bicycle battery doesn’t just depend on capacity, but is determined by the battery cells, structural design, BMS (Battery Management System), battery protection, and manufacturing process.

This article will provide a systematic analysis from a professional manufacturing perspective: how to choose an electric bicycle battery that truly stands the test of time and use.

Part 1: Choosing High-Quality Battery Cells is the Foundation of a Durable Battery

Battery cells are the “heart” of the battery, directly determining the rate of range degradation and cycle life.

1. Prioritize First-Tier or Stable Model Battery Cells

Durable electric bicycle batteries typically use:

High-consistency cylindrical battery cells (such as 18650 / 21700)

Or rigorously screened prismatic or pouch battery cells

High-quality battery cells have:

Higher cycle life (≥800–1000 cycles)

Lower internal resistance

More stable charge and discharge platform

Before mass production, all battery cells undergo capacity, internal resistance, and aging tests to ensure the consistency of the entire battery pack.

Part 2: Reasonable Battery Capacity ≠ Blindly Pursuing “Large Capacity”

Many users mistakenly believe that “the larger the capacity, the more durable,” but this is not entirely correct.

The key to durability lies in “matching”

When choosing battery capacity, you should consider:

Motor power (250W / 350W / 500W)

Actual usage scenarios (commuting / food delivery / mountain biking)

Required mileage per ride

If the capacity is constantly in a deep discharge state, it will accelerate battery aging.

In customized solutions, lithium battery manufacturers will use load calculations + usage scenario analysis to help customers choose a capacity configuration that is “not overloaded, not wasteful, and has a longer lifespan.”

Part 3: Battery Management System (BMS) Determines Long-Term Stability

A durable electric bicycle battery cannot do without a high-quality BMS. The Core Functions of a High-Quality BMS

Schutz vor Überladung/Überentladung

Überstrom- und Kurzschlussschutz

Temperature monitoring and abnormal shutdown

Cell balancing to slow down capacity degradation

Low-quality BMS often leads to:

Shorter and shorter battery life

Battery swelling and overheating

Significantly reduced cycle life

Part 4. Structural Design and Protection Level Directly Affect “How Long It Lasts”

In real-world usage environments, batteries need to withstand:

Rain and moisture

Dust and sand

Vibration and drops

High and low temperature changes

Key structural designs for long-lasting durability include:

Reinforced battery casing

Internal cushioning and fixing structures

High-level waterproof sealing (IP65/IP67)

Shockproof and anti-loosening design

Ensuring the battery remains stable and reliable in complex riding environments.

Part 5. Manufacturing Process and Consistency Determine Long-Term Reliability

Even with the same battery cells and design, batteries produced by different factories may have significantly different lifespans.

Manufacturing details that affect durability include:

Whether the spot welding process is stable

Whether the solder joints are firm and uniform

Whether the wiring harness layout is reasonable

Whether the entire battery pack undergoes aging testing

Reducing hidden faults from the source improves the consistency and lifespan of the entire battery pack.

Part 6. Choosing a Reliable Manufacturer is More Important Than Parameters

For brands and buyers, truly durable batteries come from:

Manufacturers with R&D capabilities

Long-term supply and after-sales support

Support for OEM/ODM customization

Familiarity with international market standards and application scenarios

Häufig gestellte Fragen (FAQ)

Q1: How many years do electric bicycle batteries usually last?

Under normal use and reasonable maintenance, high-quality lithium batteries typically last 3–5 years.

Q2: Is a higher cycle count always better?

The cycle count is an important indicator, but it needs to be considered in conjunction with cell quality, BMS, and usage conditions.

Q3: Does the waterproof rating affect battery life?

Yes. Good waterproof design can effectively reduce internal corrosion and short-circuit risks, significantly extending battery life.

Q4: Can I customize a battery according to my vehicle model?

Yes. Yizhan Electronics supports customized development of voltage, capacity, casing structure, interfaces, and BMS.