As the global demand for electric bicycles (eBikes) continues to accelerate, the need for safe, reliable, and customized battery solutions has never been greater. At the heart of every eBike lies its battery, the core component that determines performance, range, and rider experience. Dongguan Yizhan Electronics Technology Co., Ltd, a leading Chinese manufacturer with more than a decade of experience in lithium battery pack production, has developed a comprehensive process to deliver tailor-made eBike battery solutions for international clients.

Let’s take a look at the complete workflow behind Yizhan’s customized e-bike battery process – from initial consultation to final product delivery – and see how Yizhan combines engineering expertise, advanced manufacturing processes, and strict quality assurance to meet the diverse needs of global e-bike brands.

Why Custom eBike Batteries Matter

The eBike industry is rapidly evolving. Riders today are not only looking for longer ranges and faster charging times but also for batteries that integrate seamlessly with specific bike frames, motors, and riding environments. Off-the-shelf solutions often fail to meet these varied demands.

Voltage variety: Different eBikes require different voltages—commonly 36V, 48V, and 52V—depending on the motor system.

Capacity flexibility: Riders who use eBikes for commuting may prefer lightweight 10Ah packs, while adventure cyclists may need 20Ah or higher capacities for extended rides.

Smart safety: A robust Battery Management System (BMS) ensures stable performance by preventing overcharging, over-discharging, and overheating.

Compliance: International safety certifications such as UL, EN 50604, CE, and RoHS are essential for entering overseas markets.

By offering fully customizable battery packs, Yizhan ensures every client receives a product that matches their technical requirements, budget, and market positioning.

Step 1 – Understanding Customer Requirements

The first step in Yizhan’s customization process begins with in-depth consultation. Yizhan’s engineering and sales teams collaborate with clients to gather detailed specifications:

Desired voltage and capacity

Battery shape and dimensions to match the bike’s frame

Expected range per charge

Compatibility with motor and controller systems

Environmental requirements such as waterproofing or shock resistance

For example, a European eBike brand may request a slim Down Tube battery to fit within a compact frame design, while a North American delivery fleet may prioritize long-range Rear Rack batteries with higher amp-hour ratings.

To balance design and functionality, Yizhan engineers create CAD drawings and 3D models to simulate how the battery will be integrated into the e-bike structure. This ensures precise alignment of the battery with the frame shell and avoids costly design conflicts later in production.

Step 2 – Cell Selection & Configuration

Once the requirements are defined, the focus shifts to cell selection, which is the backbone of battery performance. Yizhan sources cells from trusted global brands, including Samsung, LG, CATL, and domestic tier-one suppliers.

Key considerations include:

Energy density: High-capacity cells provide longer riding ranges.

Cycle life: Premium cells ensure thousands of charge-discharge cycles without significant capacity loss.

Cost-performance balance: Depending on the market, Yizhan helps clients choose between premium-grade or cost-effective cells.

The next stage is determining the series and parallel (S/P) configuration. For instance:

A 10S4P configuration (10 cells in series, 4 in parallel) may provide a 36V 14Ah battery.

A 13S5P configuration is commonly used for 48V 20Ah batteries, popular among high-performance eBikes.

Each configuration is carefully designed to balance energy output, weight, and compactness, ensuring it fits seamlessly into the intended battery case.

Step 3 – Battery Management System (BMS) Integration

Safety is at the core of every Yizhan battery, which is why the BMS (Battery Management System) plays a crucial role in customization.

Yizhan offers both standard and smart BMS solutions with the following features:

Overcharge and over-discharge protection

Short-circuit prevention

Temperature monitoring with automatic cut-off

Cell balancing for longer lifespan

Bluetooth-enabled monitoring via smartphone apps

By tailoring the BMS to the client’s needs, Yizhan ensures that each eBike battery delivers consistent performance while maintaining maximum safety standards.

Step 4 – Assembly Process

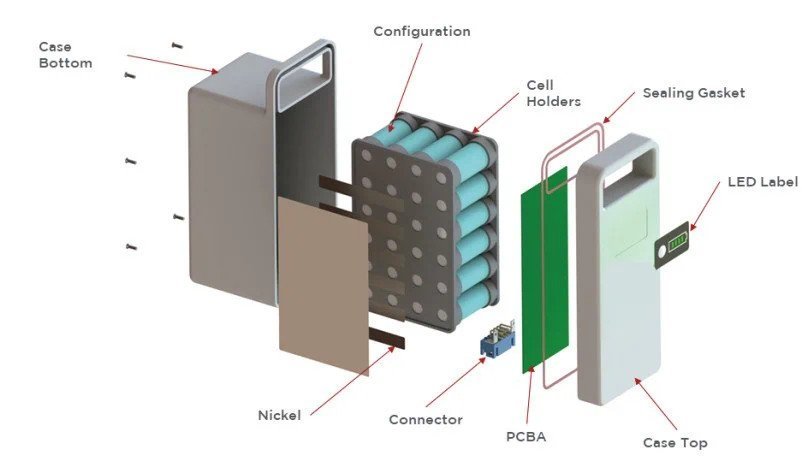

With cells and BMS selected, the assembly stage begins inside Yizhan’s modern manufacturing facilities. The process includes:

Cell Sorting & Matching: Cells are tested for internal resistance, voltage, and capacity to ensure uniformity.

Spot Welding: High-precision welding machines connect cells with nickel strips for stable conductivity.

Busbar & Harness Installation: Copper busbars and wiring harnesses are carefully arranged to maintain balance and safety.

Insulation & Protection: Each pack is wrapped in protective materials, including PVC films, spacers, and heat-shrink tubing, to prevent vibration and short circuits.

Enclosure Integration: The battery pack is housed in different case designs—Down Tube, Inner Tube, Rear Rack, or Integrated cases—based on client requirements.

The assembly process is strictly controlled under ISO-certified standards to guarantee quality consistency across every battery pack.

Step 5 – Testing & Quality Control

Before shipment, every Yizhan battery undergoes rigorous testing protocols to ensure durability and safety. Tests include:

Aging Test: Simulated charging and discharging cycles to evaluate long-term performance.

Vibration & Drop Test: Ensures batteries can withstand road shocks and transport handling.

Waterproof Test: IP-rated testing to ensure resistance against rain and splashes.

Charge/Discharge Efficiency Test: Confirms the battery delivers expected range and power output.

Certification Compliance: Batteries are verified to meet UL, CE, RoHS, and EN 50604 standards, depending on customer market requirements.

Every pack is individually tested and documented before leaving the factory, giving clients full confidence in product reliability.

Step 6 – Packaging & Global Delivery

After passing quality checks, batteries are securely packaged with foam padding, anti-static bags, and custom labeling. For OEM clients, Yizhan provides private labeling and logo printing to help brands strengthen market identity.

With years of export experience, Yizhan complies with international shipping regulations for lithium batteries, ensuring safe and efficient delivery by air, sea, or express courier. Clients around the world, from Europe to North America, benefit from Yizhan’s reliable logistics network.

Yizhan’s Competitive Edge in Custom Battery Manufacturing

Several factors distinguish Yizhan as a top-tier partner in the eBike battery industry:

12+ Years of Expertise: Deep knowledge in lithium battery engineering and assembly.

Global Clientele: Supplying OEM and ODM services to eBike brands, distributors, and fleet operators worldwide.

Advanced Facilities: Equipped with automatic welding machines, BMS testing systems, and high-capacity aging racks.

Strong R&D Team: Ability to design new battery molds, cases, and smart BMS systems.

Comprehensive After-Sales Support: Technical assistance, warranty service, and continuous improvement feedback loops.

The custom eBike battery process at Dongguan Yizhan Electronics Technology Co., Ltd. represents more than just manufacturing—it reflects a commitment to innovation, safety, and global collaboration. From initial consultation to final shipment, Yizhan ensures every battery is designed, assembled, and tested to meet the highest industry standards.

As the eBike market continues to grow worldwide, Yizhan stands ready to empower brands, OEMs, and riders with high-performance, tailor-made lithium battery solutions that deliver reliability on every ride.

For more information or to discuss your next eBike battery project, please contact!