As the global electric bike battery market continues to surge, many manufacturers, e-bike brands, and distributors are turning to custom electric bike battery solutions to meet the growing demand for higher performance, longer range, and improved safety.

A well-designed OEM e-bike battery not only boosts user experience but also strengthens the competitiveness of a brand in an increasingly crowded market.

Dongguan Yizhan Electronics Technology Co., Ltd. (Yizhan), a leading lithium battery manufacturer with 12 years of experience, shares five essential factors to consider when designing and customizing an e-bike battery that delivers both performance and reliability.

1. Voltage and Capacity: Matching the E-Bike’s Power Requirements

The first step in e-bike battery customization is determining the correct voltage and capacity to match the motor and intended usage.

-

Voltage: Common e-bike battery voltages include 36V e-bike battery, 48V e-bike battery, 52V, and 60V. Higher voltage systems often provide more torque and speed but must match the controller’s specifications.

-

Capacity (Ah): Determines how far an e-bike can travel on a single charge. Higher Ah rating for e-bike batteries means longer range, but also increases size and weight.

For example, a city commuter e-bike may use a 36V 15Ah battery for daily travel, while an off-road mountain bike might require a 48V 20Ah long-range e-bike battery for sustained performance.

Pro Tip from Yizhan: Balance range and weight. A heavy battery may provide more mileage, but it can negatively impact ride comfort and handling.

2. Lithium Battery Cell Type and Configuration

The heart of every lithium e-bike battery is its cell type and configuration. Popular chemistries include:

-

Lithium Nickel Manganese Cobalt (NMC battery) – High energy density, lightweight, performs well in different climates.

-

Lithium Iron Phosphate (LiFePO4 battery) – Exceptional cycle life, safer thermal stability, slightly heavier than NMC.

Cell formats like 18650 battery and 21700 e-bike battery also influence performance:

-

18650: Proven reliability, widely available, standard capacity.

-

21700: Higher capacity per cell, improved energy density, fewer cells for the same voltage and Ah rating.

Yizhan engineers configure series and parallel cell connections to achieve precise custom e-bike battery design specifications, ensuring the perfect balance between voltage, capacity, and durability.

3. Battery Management System (BMS) Integration

The BMS for e-bike battery is the “brain” of the pack, controlling and protecting the cells. A smart BMS for e-bike battery should provide:

-

Overcharge and over-discharge protection

-

Short-circuit prevention

-

Temperature control

-

Cell balancing for longer lifespan

Modern Bluetooth BMS for e-bike batteries even allow riders to check battery health and charging status via mobile apps.

Yizhan’s Smart BMS Advantage: Our smart BMS includes intelligent balancing, waterproof e-bike battery sealing, and compatibility with IoT fleet management for bike-sharing operators.

4. Waterproofing and Vibration Resistance

Custom e-bike batteries should meet at least IP65 waterproof e-bike battery standards to withstand rain, mud, and dust.

Key design elements for water-resistant e-bike batteries include:

-

Rubber-sealed enclosures

-

Corrosion-proof connectors

-

Internal anti-vibration padding

For rough terrain, Yizhan also designs vibration-resistant e-bike batteries with reinforced housings and secure mounting to ensure consistent performance in harsh riding conditions.

5. Custom E-Bike Battery Design, Mounting, and Branding

A custom e-bike battery design is not just about performance—it’s also about fitting perfectly into the bike’s frame and matching the brand’s identity.

Yizhan offers OEM e-bike battery casing customization, including:

-

Shape and size optimization for unique frames

-

Branding and color matching for aesthetics

-

Convenient charging port placement

Popular styles include down tube e-bike battery design, rear-rack packs, and fully integrated frame solutions.

E-Bike Battery Market Trends in 2025

In 2025, the global e-bike battery demand continues to rise due to urban mobility growth and environmental regulations.

Notable trends:

-

High-voltage e-bike batteries (52V+) for performance models

-

Faster charging technologies

-

EU Battery Regulation compliance for sustainability

-

Smart GPS tracking for rental fleets

Case Study: Yizhan Custom Lithium Battery Solutions

Dongguan Yizhan Electronics Technology Co., Ltd. has supplied thousands of Yizhan e-bike batteries worldwide, from commuter models to cargo bikes and high-performance off-road electric bicycles.

Recent OEM projects include:

-

48V waterproof e-bike battery with smart BMS for European commuters

-

36V long-range e-bike battery for North American cargo bikes

-

60V high-power vibration-resistant e-bike battery for mountain biking

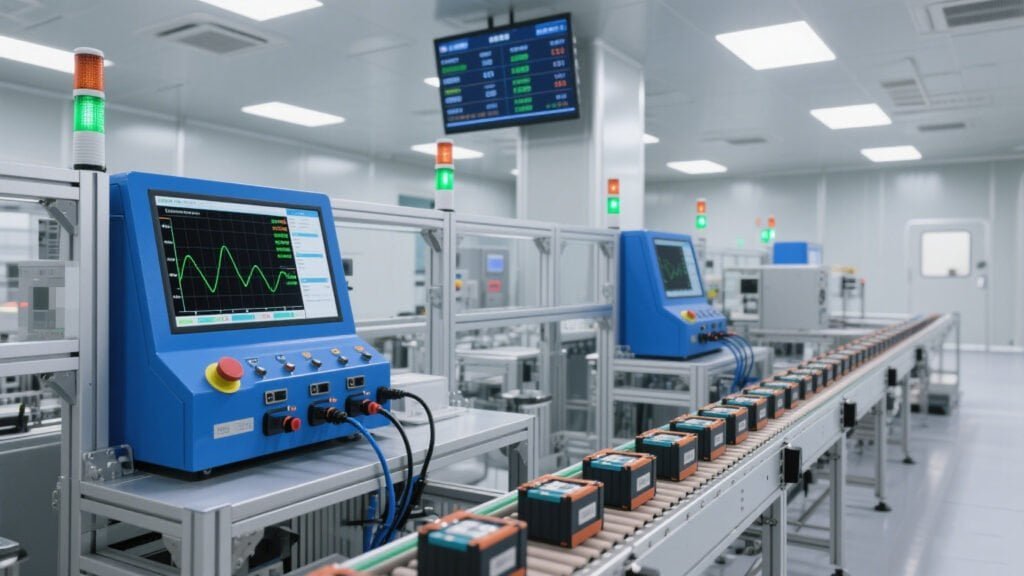

All products undergo vibration tests, EN 50604 e-bike battery compliance checks, and 100% functionality tests before shipment.

Conclusion: Designing for Performance, Safety, and Brand Value

When customizing an electric bike battery, focus on five key elements: voltage & capacity, lithium battery cell type, BMS integration, waterproofing, and custom design.

With the right partner like Yizhan, brands can ensure their OEM e-bike batteries meet international safety standards, deliver high performance, and stand out in the competitive electric bike battery market.

Media Contact:

Dongguan Yizhan Electronics Technology Co., Ltd.

Email: sales@szfirstpower.com